Product Description

Products Description

Cycling Sleeves, Cycling Headband, Cycling Gloves

|

Product name |

Cycling Sleeves, Cycling Headband, Cycling Gloves Cycling suit |

|

Packaging |

With retail packaging |

|

Printing&Logo |

OEM and ODM service are provided. |

|

Usage |

Fishing, cross-country bicycle, hiking, travel, etc |

|

Sample |

Sample is Available |

Detail Images

Q1.What bicycles do you have?

We provide various types of bicycles, which can also be customized according to customer needs.

Q2.Any discount?

The prices we quote are all wholesale price in the first place. Meanwhile, our best price will be offered according to your order quantity, so please specify your purchase quantity when you inquire. The more your order, the better discounts we will offer.

Q3.Why your price is lower than other supplier?

We are manufacturer not sale agent so we can cut the agent fees out .

Q4.When are your service hours?

We will be online 24hours each day,and solve your questions asap.

Q5.How about quality of products?

We guarantee strict control on every detail of the products. Each product is carefully inspected and tested before delivery.

Q6.How about quality of products?

Usually within 15~20 days. It depends on your order quantity as well.

Q7.Can you produce according to the samples?

Yes, we can produce by your samples or technical drawings. We can build the molds and fixtures.

Q8.Do you test all your goods before delivery?

Yes, we have 100% test before delivery.

Q9.How do you make our business long-term and good relationship?

We keep good quality and competitive price to ensure our customers benefit

Q10.Can I get some samples?

We are honored to send you samples for quality check.

| Age: | Adults |

|---|---|

| Gender: | Unisex |

| Material: | Ice Silk Nylon |

| Type: | Cycling Headband Gloves Sleeves Set |

| Feature: | Breathable, Quick-Drying, Body Shape, Waterproof, Windbreak, Moisture-Wicking, Anti-Static, Anti-UV, Rip-Stop, Flame-Retardant |

| Usage: | Ball Sports, Soccer, Racing, Cycling, Fitness, Ski, Rugby/Football, Track and Field, Water Sports, Gym, Yoga, Basketball, Hockey, Martial Arts & Boxing, Rockcraft, Dancing, Tennis, Equestrian |

| Customization: |

Available

| Customized Request |

|---|

Can sun gears be used in automotive applications?

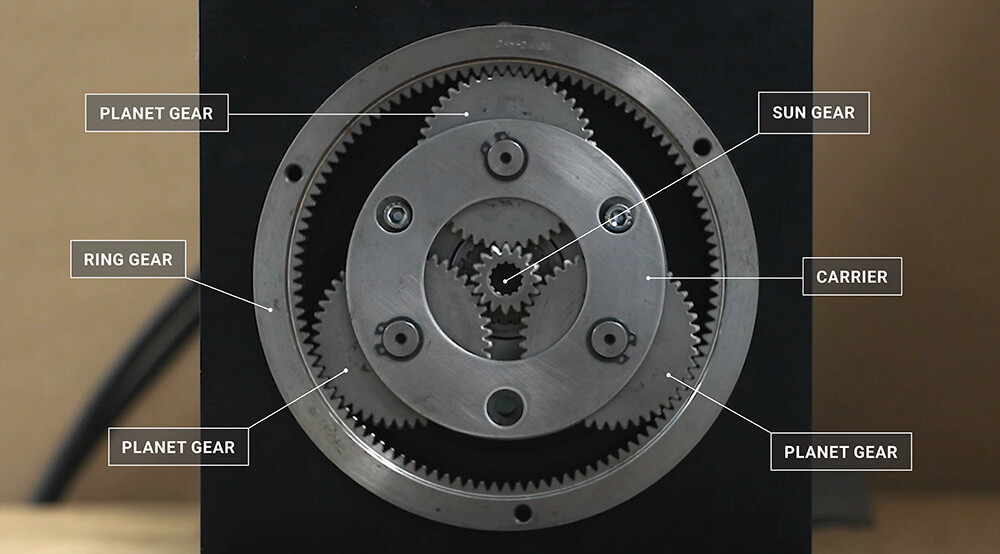

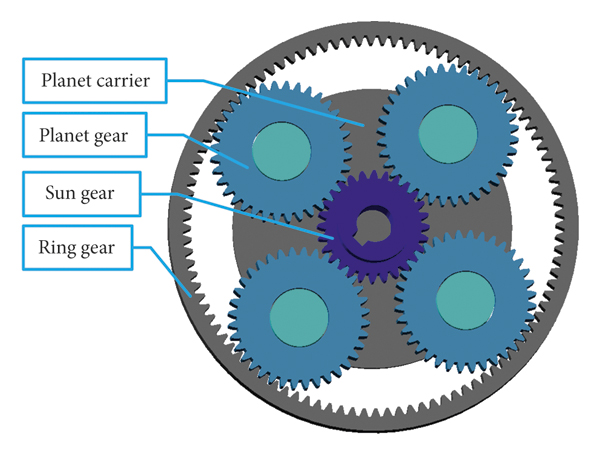

Sun gears are widely used in various automotive applications, playing crucial roles in different systems. Let’s explore the automotive applications where sun gears are commonly employed:

- Automatic Transmissions:

Sun gears are integral components of automatic transmissions in vehicles. Automatic transmissions use planetary gear systems, where the sun gear is one of the key elements. The interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and smooth shifting between gears.

In automatic transmissions, the sun gear is driven by the engine’s input shaft and transmits power to the other gears. By controlling the engagement of various clutches and brakes within the transmission, the sun gear enables seamless gear changes, optimizing vehicle performance and fuel efficiency.

- Transfer Cases:

In four-wheel-drive and all-wheel-drive vehicles, transfer cases distribute power between the front and rear wheels. Sun gears are utilized in transfer cases to facilitate power transfer and gear reduction.

The sun gear, along with other gears and components, helps control the torque distribution and gear ratios between the front and rear axles. This allows vehicles to adapt to different driving conditions, such as slippery surfaces or off-road terrain, enhancing traction and stability.

- Starter Motors:

Sun gears are employed in starter motors, which are responsible for cranking the engine during startup. Starter motors use a gear reduction mechanism to convert the electric motor’s high-speed rotation into a higher torque output.

The sun gear, along with other gears like the planetary gears, enables the gear reduction necessary to generate sufficient torque to crank the engine. This gearing arrangement allows for efficient and reliable engine starting, even in challenging conditions.

- Power Seats and Windows:

Sun gears can also be found in power seat and power window mechanisms in vehicles. These systems use electric motors to adjust seat positions or operate windows.

The sun gear, along with other gears and mechanisms, converts the rotational motion of the electric motor into linear movement, enabling precise adjustments of seat positions or smooth operation of windows. The use of sun gears ensures reliable and efficient functionality of these systems.

- Other Automotive Systems:

Sun gears may also have applications in other automotive systems. For example, they can be found in power steering systems, where they contribute to the gear reduction and power transmission required for smooth steering operation.

Furthermore, sun gears can be utilized in various auxiliary systems, such as cooling fans, HVAC (heating, ventilation, and air conditioning) systems, and engine accessories. These applications leverage the sun gear’s ability to facilitate power transmission and gear reduction, enhancing the efficiency and performance of these systems.

In summary, sun gears are extensively used in automotive applications, including automatic transmissions, transfer cases, starter motors, power seats and windows, power steering systems, and auxiliary systems. Their presence in these systems enables crucial functions such as gear shifting, power distribution, gear reduction, and efficient power transmission. Sun gears contribute to the overall performance, reliability, and functionality of automotive systems, enhancing the driving experience and vehicle efficiency.

Can sun gears be used in high-torque applications?

Sun gears can indeed be used in high-torque applications and are commonly employed in various mechanical systems that require substantial torque transmission. The design and characteristics of sun gears make them capable of handling significant torque loads. Here’s an explanation of why sun gears can be used in high-torque applications:

- Central Positioning: Sun gears are typically located at the center of planetary gear arrangements. This central positioning allows them to distribute torque to multiple planet gears, which then transfer the torque to the outer ring gear. The central position of the sun gear enables efficient torque transmission and load sharing among the gears, making it suitable for handling high-torque applications.

- Torque Amplification: The arrangement of sun gears in a planetary gear system allows for torque amplification. By utilizing the interaction between the sun gear, planet gears, and ring gear, the gear system can multiply or reduce torque based on the gear ratio configuration. In high-torque applications, this torque amplification capability of sun gears is advantageous as it allows for the multiplication of input torque, resulting in higher torque output.

- Sturdy Construction: Sun gears are designed to withstand high torque forces. They are usually made from durable materials such as hardened steel or other alloys with high tensile strength. This robust construction ensures that sun gears can effectively handle the transmitted torque without experiencing excessive wear or deformation.

- Load Distribution: The interaction between the sun gear, planet gears, and ring gear in a planetary gear system enables effective load distribution. By distributing the torque across multiple planet gears, the load is shared, reducing the stress on individual gears. This load distribution mechanism enhances the overall durability and torque-handling capacity of the gear system, making it suitable for high-torque applications.

- Customizable Gear Ratios: Sun gears in planetary systems allow for the customization of gear ratios. By changing the number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, the gear ratio can be tailored to meet specific application requirements. This flexibility in gear ratio control enables the optimization of torque output for high-torque applications.

In summary, sun gears can be effectively used in high-torque applications due to their central positioning, torque amplification capability, sturdy construction, load distribution mechanism, and customizable gear ratios. These characteristics make sun gears reliable and suitable for transmitting substantial torque in various mechanical systems.

What is the purpose of using a sun gear in mechanical applications?

The use of a sun gear in mechanical applications serves several important purposes. This central gear component plays a crucial role in achieving specific functionalities and benefits within gear systems. Here’s an explanation of the purpose of using a sun gear:

- Power Transmission: The primary purpose of a sun gear is to facilitate power transmission within gear systems. It acts as a central driver that receives power input, typically from an external source such as an engine or motor. The sun gear transfers torque to other gears, enabling the transmission of rotational motion and power throughout the system.

- Gear Ratio Control: Sun gears are instrumental in controlling the gear ratio within a gear system. By altering the size, number of teeth, and interaction with other gears such as planet gears and ring gears, the sun gear helps determine the overall gear ratio. This allows for the adjustment of rotational speed and torque output according to the specific requirements of the mechanical application.

- Torque Multiplication: In certain gear systems, a sun gear can be used to multiply torque. By employing a planetary gear arrangement, where the sun gear interacts with multiple planet gears and an outer ring gear, torque can be amplified. This torque multiplication capability of the sun gear is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Sun gears can also play a role in controlling the direction of power transmission within gear systems. In planetary gear arrangements, fixing or holding the sun gear while the ring gear or planet carrier is driven can result in different output directions, such as forward or reverse rotation. This directional control feature adds versatility to gear systems, allowing them to be utilized in various mechanical applications.

- Compact Design: The utilization of a sun gear in gear systems often enables a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions.

In summary, the purpose of using a sun gear in mechanical applications is to facilitate power transmission, control gear ratios, provide torque multiplication, offer directional control, and enable compact designs. The specific application and requirements of a mechanical system determine the selection and utilization of sun gears, ensuring efficient and reliable operation in various industries such as automotive, aerospace, industrial machinery, and more.

editor by CX 2023-10-07