Product Description

Product Description

Product Parameters

| Item | Spur Gear Axle Shaft |

| Material | 4140,4340,40Cr,42Crmo,42Crmo4,20Cr,20CrMnti, 20Crmo,35Crmo |

| OEM NO | Customize |

| Certification | ISO/TS16949 |

| Test Requirement | Magnetic Powder Test, Hardness Test, Dimension Test |

| Color | Paint , Natural Finish ,Machining All Around |

| Material | Aluminum: 5000series(5052…)/6000series(6061…)/7000series(7075…) |

| Steel: Carbon Steel,Middle Steel,Steel Alloy,etc. | |

| Stainess Steel: 303/304/316,etc. | |

| Copper/Brass/Bronze/Red Copper,etc. | |

| Plastic:ABS,PP,PC,Nylon,Delrin(POM),Bakelite,etc. | |

| Size | According to Customer’s drawing or samples |

| Process | CNC machining,Turning,Milling,Stamping,Grinding,Welding,Wire Injection,Cutting,etc. |

| Tolerance | ≥+/-0.03mm |

| Surface Treatment | (Sandblast)&(Hard)&(Color)Anodizing,(Chrome,Nickel,Zinc…)Plating,Painting,Powder Coating,Polishing,Blackened,Hardened,Lasering,Engraving,etc. |

| File Formats | ProE,SolidWorks,UG,CAD,PDF(IGS,X-T,STP,STL) |

| Sample | Available |

| Packing | Spline protect cover ,Wood box ,Waterproof membrane; Or per customers’ requirements. |

Our Advantages

Why Choose US ???

1. Equipment :

Our company boasts all necessary production equipment,

including Hydraulic press machines, Japanese CNC lathe (TAKISAWA), Korean gear hobbing machine (I SNT), gear shaping machine, machining center, CNC grinder, heat treatment line etc.

2. Processing precision:

We are a professional gear & gear shafts manufacturer. Our gears are around 6-7 grade in mass production.

3. Company:

We have 90 employees, including 10 technical staffs. Covering an area of 20000 square meters.

4. Certification :

Oue company has passed ISO 14001 and TS16949

5.Sample service :

We provide free sample for confirmation and customer bears the freight charges

6.OEM service :

Having our own factory and professional technicians,we welcome OEM orders as well.We can design and produce the specific product you need according to your detail information

Cooperation Partner

Company Profile

Our Featured Products

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Manufacturing Method: | Cast Gear |

| Toothed Portion Shape: | Spur Gear |

| Material: | Stainless Steel |

| Type: | Circular Gear |

| Yield: | 5, 000PCS / Month |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does the size of a sun gear affect the gear ratio in planetary systems?

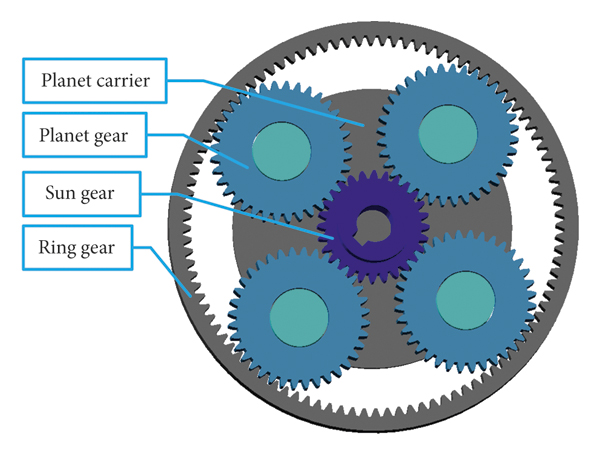

The size of the sun gear plays a significant role in determining the gear ratio in planetary gear systems. The gear ratio determines the relationship between the input speed and torque and the output speed and torque in the system. Here’s an explanation of how the size of the sun gear affects the gear ratio in planetary systems:

- Direct Proportion:

In a planetary gear system, the gear ratio is influenced by the relative sizes of the sun gear, planet gears, and ring gear. The gear ratio is typically expressed as the ratio of the output speed to the input speed or the ratio of the output torque to the input torque.

When considering the size of the sun gear, it is important to understand that the gear ratio is inversely proportional to the size of the sun gear. In other words, as the size of the sun gear increases, the gear ratio decreases, and vice versa.

- Power Distribution:

The size of the sun gear affects the power distribution within the planetary system. As the sun gear rotates, it engages with the planet gears, which, in turn, mesh with the ring gear. The interaction between these gears determines the gear ratio.

A larger sun gear allows for a higher number of teeth on the sun gear itself as well as on the planet gears. This means that each rotation of the sun gear will result in a smaller rotation of the planet gears and the ring gear. Consequently, a larger sun gear leads to a lower gear ratio, reducing the output speed and increasing the output torque.

- Torque Amplification:

Another factor influenced by the size of the sun gear is torque amplification. In planetary gear systems, the sun gear’s size affects the torque multiplication or reduction capabilities of the system.

With a larger sun gear, the system can provide higher torque output for a given input torque, resulting in torque amplification. This can be advantageous in applications where increased torque is required, such as during vehicle acceleration or heavy load conditions.

Conversely, a smaller sun gear reduces the torque output of the system, resulting in torque reduction. This can be useful in situations where a lower torque output is desired, such as when precise control is required or when operating in low-torque applications.

- Overall Gear Ratio Range:

The size of the sun gear also affects the overall gear ratio range that can be achieved in a planetary system. By varying the size of the sun gear relative to the other gears, different gear ratios can be achieved, allowing for a wider range of output speeds and torques.

For example, if a system requires a higher gear ratio range, a larger sun gear can be used in combination with appropriately sized planet gears and a ring gear. Conversely, if a lower gear ratio range is desired, a smaller sun gear can be employed.

It’s important to note that the size of the sun gear alone does not determine the gear ratio. The gear ratio is influenced by the combination of the sizes of all the gears within the planetary system.

In summary, the size of the sun gear in a planetary gear system has a direct impact on the gear ratio, power distribution, torque amplification, and overall gear ratio range. A larger sun gear results in a lower gear ratio, while a smaller sun gear leads to a higher gear ratio. The size of the sun gear, along with the sizes of the other gears, determines the performance characteristics of the planetary system.

Can you explain the function of a sun gear in automatic transmissions?

The sun gear plays a crucial role in the operation of automatic transmissions. It is an essential component within the planetary gear set, which is responsible for transmitting power and controlling gear ratios in automatic transmissions. Here’s an explanation of the function of a sun gear in automatic transmissions:

- Power Input:

The sun gear serves as one of the primary power input sources in an automatic transmission. It connects to the torque converter, which is a fluid coupling that transfers engine power to the transmission. The rotation of the sun gear receives torque from the engine and acts as the initial input for the gear set.

- Gear Ratio Control:

The sun gear, along with other gears in the planetary gear set, allows for the control of gear ratios in an automatic transmission. By varying the engagement and rotation of the sun gear, different gear ratios can be achieved, providing the desired combination of torque multiplication and speed reduction or increase.

The gear ratio control is achieved through the interaction between the sun gear, planet gears, and ring gear. The sun gear is connected to the planet gears, which in turn mesh with the ring gear. The arrangement and rotation of these gears determine the gear ratio and, consequently, the output speed and torque of the transmission.

- Forward and Reverse Operation:

The sun gear’s function also extends to enabling both forward and reverse operation in automatic transmissions. By controlling the engagement of the sun gear with other gears in the planetary set, the transmission can switch between forward and reverse directions.

In the forward operation, the sun gear engages with the planet gears and the ring gear, transmitting power from the input shaft to the output shaft with a specific gear ratio. In the reverse operation, the sun gear engages with a different set of gears, causing the rotation of the output shaft to reverse its direction.

- Torque Multiplication:

Another important function of the sun gear is torque multiplication. By utilizing the planetary gear set arrangement, the sun gear can multiply or reduce torque depending on the gear ratio configuration. This torque multiplication capability allows the transmission to provide higher torque output when needed, such as during acceleration or climbing steep gradients.

- Gear Shifts:

The sun gear’s function also contributes to smooth and efficient gear shifts in automatic transmissions. As gear shifts occur, the transmission control unit adjusts the engagement of the sun gear, planet gears, and ring gear to achieve the desired gear ratio for the target speed and load conditions.

During gear shifts, the engagement of clutches or bands controlled by the transmission control unit ensures that the sun gear rotates with the desired set of gears, allowing for seamless transitions between different gear ratios. This coordinated operation of the sun gear and other gears facilitates smooth acceleration and deceleration without excessively straining the transmission components.

In summary, the sun gear in automatic transmissions serves multiple functions, including power input from the torque converter, gear ratio control through its engagement with other gears, enabling forward and reverse operation, torque multiplication for increased output, and contributing to smooth gear shifts. These functions collectively allow automatic transmissions to provide efficient power transfer, dynamic gear ratios, and smooth operation in various driving conditions.

What is the purpose of using a sun gear in mechanical applications?

The use of a sun gear in mechanical applications serves several important purposes. This central gear component plays a crucial role in achieving specific functionalities and benefits within gear systems. Here’s an explanation of the purpose of using a sun gear:

- Power Transmission: The primary purpose of a sun gear is to facilitate power transmission within gear systems. It acts as a central driver that receives power input, typically from an external source such as an engine or motor. The sun gear transfers torque to other gears, enabling the transmission of rotational motion and power throughout the system.

- Gear Ratio Control: Sun gears are instrumental in controlling the gear ratio within a gear system. By altering the size, number of teeth, and interaction with other gears such as planet gears and ring gears, the sun gear helps determine the overall gear ratio. This allows for the adjustment of rotational speed and torque output according to the specific requirements of the mechanical application.

- Torque Multiplication: In certain gear systems, a sun gear can be used to multiply torque. By employing a planetary gear arrangement, where the sun gear interacts with multiple planet gears and an outer ring gear, torque can be amplified. This torque multiplication capability of the sun gear is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Sun gears can also play a role in controlling the direction of power transmission within gear systems. In planetary gear arrangements, fixing or holding the sun gear while the ring gear or planet carrier is driven can result in different output directions, such as forward or reverse rotation. This directional control feature adds versatility to gear systems, allowing them to be utilized in various mechanical applications.

- Compact Design: The utilization of a sun gear in gear systems often enables a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions.

In summary, the purpose of using a sun gear in mechanical applications is to facilitate power transmission, control gear ratios, provide torque multiplication, offer directional control, and enable compact designs. The specific application and requirements of a mechanical system determine the selection and utilization of sun gears, ensuring efficient and reliable operation in various industries such as automotive, aerospace, industrial machinery, and more.

editor by CX 2023-10-25