Product Description

Product Description

We(HangZhou BST) export construction machinery parts, specializes in the manufacturing and supplying of Shantui, Cat and komat su parts for over 15 years. Our company has a complete range such as engine parts ,transmission parts,hydraulic parts, electrical parts,drive parts,undercarriage parts, filter. Models such as komats D60/80/155,PC2

175-15-42322

09232-5715

571-5715

175-15-41140

706-7L-01110

209-27-00160

209-27-71370

21n-27-31330

209-27-61360

198-09-31630

209-27-71521

21n-27-31310

21n-27-31110

209-27-71330 Spitter

209-27-71261

207-27-61230

20Y-27-21250

209-27-71480

20Y-27-21290

209-27-71141

209-27-71410

21n-27-31250

209-27-71390

21n-27-31260

208-27-61350

20y-27-21240

209-27-71350

20G-26-11240

209-27-71310

20Y-27-21280

21n-27-31120

21n-27-31210

21n-27-31221

21n-27-00150

21n-27-31120

21n-09-31120

209-38-73360

06030-06219

06030- 0571 4

04070-00140

209-38-73170

07002-22434

07030-03034

07005-03016

209-38-73130

209-38-73140

06000-23124

07000-15335

21n-26-31140

208-26-52263

208-26-61291

21n-26-31110

20Y-27-21250

208-26-63140

207-27-63210

207-27-63230

20y-27-13310

208-26-63131

207-26-61180

207-27-63250

20Y-27-11250

208-26-63110

208-26-61151

20Y-27-22210

| Part name | Part No. | Des |

| Shantui Alternator | 4060811 | Shantui dozer parts |

| Shantui Alternator | 3016627 | Shantui dozer parts |

| Shantui Alternator | 4061007 | Shantui dozer parts |

| Shantui Alternator | VG1095094002 | Shantui dozer parts |

| Shantui Alternator | 6N9294/5S9088 | Shantui dozer parts |

| Shantui Alternator | D11-102-13 | Shantui dozer parts |

| Shantui Alternator | 13571500/4110000054053 | Shantui dozer parts |

| Shantui Alternator | 13571345/411000571005 | Shantui dozer parts |

| Alternator | JFZ279 | 28V 70A |

| Alternator | JFZ273 | 28V 70A |

| Alternator | JFZ276 | 28V 70A |

| Alternator | AVI136 series | 28V 70A |

| Alternator | AVI144 series | 28V 100A/14V 150A |

| Alternator | JFZ210/211 series | 28V 100A-110A |

| Alternator | 8LHA3096UC | 28V 110A |

| Alternator | 8LHA3040UC | 28V 120A |

| Alternator | 8SC3141VC series | 28V 140A-150A |

| Alternator | AC172RA series | 28V 140A |

| Alternator | AVi168A series | 28V 150A |

| Alternator | AVi168W series | 28V 150A |

| Alternator | AVi168F3001 | 28V 150A |

| Alternator | 8SC3239VC series | 28V 150A |

| Alternator | 8SC3238VC series | 28V 150A |

| Alternator | 8SC3110VC series | 28V 150A |

| Alternator | AVi147 series | 28V 120A |

| Alternator | AVi147 series | 28V 120A |

| Alternator | AVE2119-E | 28V 110A |

| Alternator | AViC2002C | 28V 70A |

| AOBO series | ||

| Alternator | JFZ2922 | 28V 55A |

| Alternator | JFZ2200C | 28V 70A |

| Alternator | JFZ2971A | 28V 75A |

| Alternator | JFZ2971B | 28V 75A |

| Alternator | JFZ2971D | 28V 75A |

| Alternator | JFZ2150 | 28V 150A |

| Alternator | HOWO | 28V 80A |

| Alternator | HOWO3000 | 28V 80A |

| series | ||

| Alternator | CA1666IR | 28V 80A |

| Alternator | CA1693IR | 28V 110A |

| Alternator | CA1148IR | 28V 80A |

| Alternator | CA907IR | 28V 80A |

| Alternator | CA550IR | 28V 55A |

| Alternator | CA1593IR | 28V 80A |

| Alternator | CA1699IR | 28V 80A |

| Alternator | CA853IR | 28V 80A |

| Alternator | CA1236IR | 28V 140A |

| Alternator | CA1237IR | 28V 140A |

| Alternator | CA1853IR | 28V 80A |

| Alternator | CA1883IR | 28V 110A |

| DENSO series | ||

| Alternator | DENSO series | 28V 95A |

| Alternator | DENSO series | 14V 130A |

| Alternator | Delco 24SI series | 28V 70A |

FAQ

Q1:You are a trader or manufacturer .

We are a trader .

Q2: How about the payment terms ?

We usually accept T/T . Other terms also could be negotiated .

Q3: Warranty

3-6 months warranty. If any parts break during the warranty, Just offer us the proof . We’ll send you a new 1 !

Q5:If parts be lost during delivery , how solve ?

We’ll resend the parts free of charge .

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Type: | Crawler |

| Application: | Excavator |

| Certification: | ISO9001: 2000 |

| Condition: | New |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

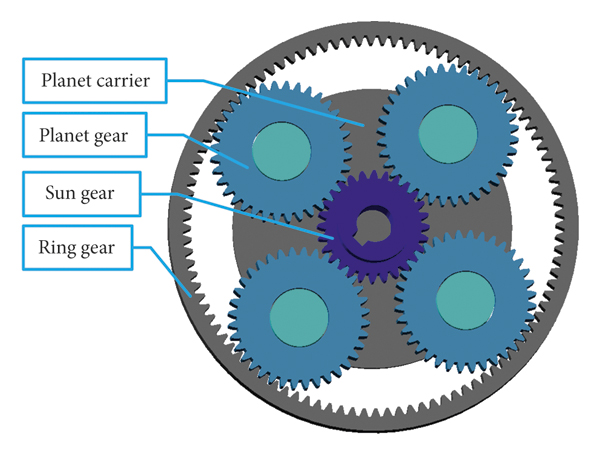

How does a sun gear contribute to the overall efficiency of a gear arrangement?

A sun gear plays a significant role in determining the overall efficiency of a gear arrangement. Let’s explore how a sun gear contributes to the efficiency of a gear system:

- Power Transmission:

The sun gear serves as the primary driver in many gear systems, transmitting power from the input source to the output component. Its contribution to power transmission efficiency is crucial. A well-designed sun gear ensures minimal power loss during the transfer of rotational force.

Efficiency is influenced by factors such as gear material, surface finish, and lubrication. The sun gear’s design, including its tooth profile, size, and alignment with other gears, affects the smoothness of power transmission, minimizing energy losses due to friction and misalignment.

- Load Distribution:

The interaction between the sun gear and other gears, such as planet gears or ring gears, influences load distribution within the gear arrangement. An efficient sun gear design ensures that the load is evenly distributed across all engaged gears, reducing the stress on individual gear teeth.

Uniform load distribution helps prevent premature wear and damage to the gears, enhancing overall efficiency and extending the gear system’s lifespan. By efficiently distributing the load, the sun gear contributes to a more balanced distribution of forces within the gear arrangement.

- Reduced Friction and Wear:

The sun gear’s smooth operation is vital for minimizing friction and wear within the gear system. When the sun gear meshes with other gears, such as planet gears or ring gears, it should have proper tooth engagement and alignment.

An accurately designed sun gear reduces sliding friction and ensures a rolling contact between the gear teeth. This rolling contact reduces wear, heat generation, and energy losses due to friction. By minimizing friction and wear, the sun gear enhances the overall efficiency of the gear arrangement.

- Optimized Gear Ratios:

The sun gear’s size and its relationship to other gears in the arrangement significantly impact the gear ratios. Efficient gear ratios are essential for achieving the desired output speed and torque in a gear system.

An optimized sun gear design, along with carefully selected sizes for other gears, allows for efficient gear ratio selection. This ensures that the gear system operates within the desired speed and torque range, maximizing the overall efficiency of the arrangement.

- Minimized Energy Losses:

An efficient sun gear design aims to minimize energy losses within the gear arrangement. Energy losses can occur due to factors such as friction, misalignment, and inefficient power transmission.

By focusing on factors like gear tooth profile, material selection, lubrication, and proper alignment, the sun gear can contribute to the reduction of energy losses. Minimizing energy losses improves the overall efficiency of the gear arrangement, ensuring more effective utilization of input power.

- System Optimization:

The sun gear’s contribution to the overall efficiency of a gear arrangement is part of a broader system optimization process. Engineers consider various factors, including gear design, material selection, lubrication, and operating conditions, to maximize the efficiency of the entire gear system.

The sun gear, as a vital component, is optimized in conjunction with other gears and system parameters to achieve the desired efficiency levels. Its design and performance directly impact the overall efficiency of the gear arrangement.

In conclusion, the sun gear’s contribution to the overall efficiency of a gear arrangement lies in its role in power transmission, load distribution, friction reduction, optimized gear ratios, and minimizing energy losses. By considering these factors and optimizing the sun gear’s design, engineers can enhance the efficiency and performance of gear systems in various applications.

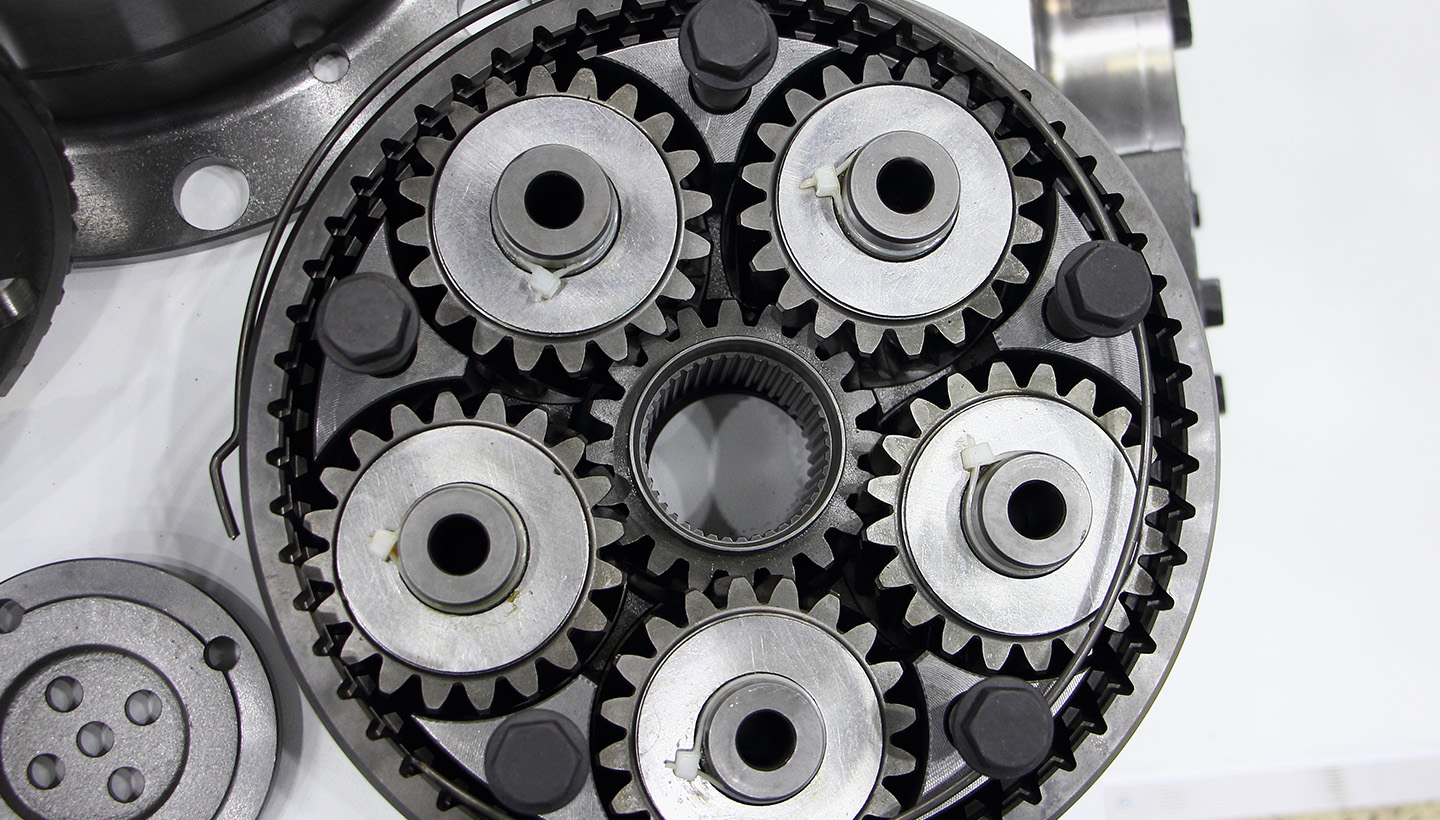

What is the role of a sun gear in the operation of a differential gear system?

The sun gear plays a vital role in the operation of a differential gear system, which is commonly used in vehicles to distribute power between the wheels while allowing them to rotate at different speeds. The sun gear, along with other gears in the differential, contributes to the smooth and efficient operation of the system. Here’s an explanation of the role of a sun gear in the operation of a differential gear system:

- Power Input:

The sun gear serves as the input for the differential gear system. It receives torque from the driveshaft or propeller shaft, which transfers power from the engine or transmission to the differential. The rotation of the sun gear initiates the power flow within the differential assembly.

- Speed Differentiation:

The primary function of the differential gear system is to allow the wheels to rotate at different speeds while distributing power between them. The sun gear, along with the other gears in the differential, enables this speed differentiation.

As the sun gear rotates, it meshes with the planet gears, which are arranged around it. The planet gears, in turn, engage with the ring gear, which is connected to the axle shafts leading to the wheels. The interaction between the sun gear, planet gears, and ring gear allows the differential to accommodate different rotational speeds of the wheels.

- Distribution of Torque:

Another critical role of the sun gear is to distribute torque between the wheels in a differential system. The torque input from the sun gear is transmitted to the planet gears, which then transfer the torque to the ring gear and, subsequently, to the axle shafts and wheels.

As the differential operates, it adjusts the distribution of torque based on the traction and resistance encountered by each wheel. If one wheel experiences less resistance or has more traction than the other, the differential will allocate more torque to that wheel. This torque distribution helps optimize power delivery, improve traction, and enhance vehicle stability during cornering or uneven road conditions.

- Equal Torque Split (Open Differential):

In an open differential system, which is the most common type, the sun gear plays a role in equal torque split between the wheels under normal driving conditions. When both wheels have equal traction and resistance, the sun gear distributes torque equally to the planet gears, resulting in an equal torque split between the wheels.

However, in situations where one wheel loses traction or encounters less resistance, such as during wheel slip or when one wheel is on a slippery surface, the open differential will prioritize torque delivery to the wheel with less traction, potentially reducing overall traction and performance.

- Limited-Slip Differential:

In some differential systems, such as limited-slip differentials (LSDs), the sun gear’s role is modified to provide improved traction and torque distribution. LSDs use various mechanisms, such as clutch packs or viscous fluids, to limit the speed differentiation between the wheels and redirect torque to the wheel with more traction.

In LSDs, the sun gear’s engagement with the other gears is modified to allow for controlled torque transfer, enhancing traction and stability during challenging driving conditions.

In summary, the sun gear in a differential gear system serves as the power input and enables speed differentiation and torque distribution between the wheels. Its role is crucial for ensuring smooth power delivery, optimizing traction, and enhancing vehicle stability in various driving conditions.

What is the significance of the positioning of the sun gear in planetary gear arrangements?

The positioning of the sun gear in planetary gear arrangements holds significant importance and directly impacts the functionality and performance of the gear system. Understanding the significance of sun gear positioning helps in comprehending how different configurations can be utilized to achieve specific objectives. Here’s an explanation of the significance of the positioning of the sun gear in planetary gear arrangements:

- Power Input: The sun gear serves as the primary power input element in a planetary gear arrangement. Its central position allows it to receive rotational motion and torque from an external source, such as an engine or motor. Being the input gear, the sun gear plays a crucial role in transmitting power to other gears within the system.

- Interaction with Planet Gears: The positioning of the sun gear at the center of a planetary gear arrangement enables its engagement with multiple planet gears. The planet gears, which are smaller gears surrounding the sun gear, mesh with both the sun gear and an outer ring gear. This interaction between the sun gear and planet gears facilitates the transfer of torque and motion between the gears.

- Torque Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the outer ring gear. The positioning of the sun gear, along with the arrangement of the planet gears and ring gear, allows for torque distribution among the gears. This torque distribution mechanism enables efficient load sharing and prevents excessive stress on any single gear, enhancing the overall durability and performance of the gear system.

- Gear Ratio Control: The positioning of the sun gear in relation to the planet gears and the ring gear determines the gear ratio of the planetary gear arrangement. By changing the arrangement and sizes of these gears, different gear ratios can be achieved. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, play a crucial role in determining the gear ratio. This flexibility in gear ratio control allows for the customization of output speeds and torque levels to suit specific application requirements.

- Torque Amplification: The positioning of the sun gear in a planetary gear arrangement enables torque amplification. By utilizing the interaction between the sun gear, planet gears, and ring gear, the gear system can multiply or reduce torque based on the gear ratio configuration. This torque amplification feature is particularly advantageous in applications where high torque output is needed, such as automotive transmissions and heavy machinery.

- Directional Control: The positioning of the sun gear also contributes to the directional control capability of a planetary gear arrangement. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control adds versatility to the gear system, allowing it to be used in various mechanical applications.

In summary, the positioning of the sun gear in planetary gear arrangements is significant for power input, interaction with planet gears, torque distribution, gear ratio control, torque amplification, and directional control. The central position of the sun gear enables efficient power transmission, load sharing, and customization of gear ratios, making planetary gear arrangements with a sun gear suitable for a wide range of mechanical applications.

editor by CX 2023-11-02