Product Description

Click Here Get More Information

Our Advantages

Equipment

3-axis, 4-axis and full 5-axis processing equipment, CNC lathe, centering machine, turning and milling compound, wire cutting, EDM, grinding, etc

Processing

CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding

Materials

Aluminum, metal, steel, metal, plastic, metal, brass, bronze, rubber, ceramic, cast iron, glass, copper, titanium, metal, titanium, steel, carbon fiber, etc

Tolerance

+/-0.01mm, 100% QC quality inspection before delivery, can provide quality inspection form

Quality Assurance

ISO9001:2015, ISO13485:2016, SGS, RoHs, TUV

Tolerance

Surface Treatment

| Aluminum parts | Stainless Steel parts | Steel parts | Brass parts |

| Clear Anodized | Polishing | Zinc Plating | Nickel Plating |

| Color Anodized | Passivating | Oxide black | chrome plating |

| Sandblast Anodized | Sandblasting | Nickel Plating | Electrophoresis black |

| Chemical Film | Laser engraving | Chrome Plating | Oxide black |

| Brushing | Electrophoresis black | Carburized | Powder coated |

| Polishing | Oxide black | Heat treatment |

Machining Workshop

Production Process

Quality Guarantee

Click Here Get Free Quotation

Application industry

CNC Machining Parts Can Be Used in Many Industry

Aerospace/ Marine/ Metro/ Motorbike/ Automotive industries, Instruments & Meters, Office equipments, Home appliance, Medical equipments, Telecommunication, Electrical & Electronics, Fire detection system, etc

Areospace

Cylinder Heads, Turbochargers, Crankshafts, Connecting Rods Pistons, Bearing Caps, CV Joints, Steering Knuckles, Brake Calipers,Gears,Differential Housing, Axle Shafts

Auto&Motorcycle

Cylinder Heads, Turbochargers, Crankshafts, Connecting Rods Pistons,Bearing Caps, CV Joints, Steering Knuckles, Brake Calipers,Gears, Differential Housing, Axle Shafts

Energy

Drill Pipes and Casing, Impellers Casings, Pipe Control Valves, Shafts, Wellhead Equipment, Mud Pumps, Frac Pumps, Frac Tools,Rotor Shafts and disc

Robotics

Custom robotic end-effectors, Low-volume prototype, Pilot, Enclosures, Custom tooling, Fixturing

Medical Industry

Rotary Bearing Seal Rings for CHINAMFG Knife,CT Scanner Frames,Mounting Brackets,Card Retainers for CT Scanners,Cooling Plenums for CT Scanners,Brackets for CT Scanners,Gearbox Components,Actuators,Large Shafts

Home Appliances

Screws, hinges, handles, slides, turntables, pneumatic rods, guide rails, steel drawers

Certifications

FAQ

Q1. What kind of production service do you provide?

CNC machining, CNC Turning, CNC Milling, Welding, Laser Cutting, Bending, Spinning, Wire Cutting, Stamping, Electric Discharge Machining (EDM), Injection Molding, Simple Assembly and Various Metal Surface Treatment.

Q2. How about the lead time?

Mould : 3-5 weeks

Mass production : 3-4 weeks

Q3. How about your quality?

♦Our management and production executed strictly according to ISO9001 : 2008 quality System.

♦We will make the operation instruction once the sample is approval.

♦ We will 100% inspect the products before shipment.

♦If there is quality problem, we will supply the replacement by our shipping cost.

Q4. How long should we take for a quotation?

After receiving detail information we will quote within 24 hours

Q5. What is your quotation element?

Drawing or Sample, Material, finish and Quantity.

Q6. What is your payment term?

Mould : 50% prepaid, 50% after the mould finish, balance after sample approval.

Goods : 50% prepaid, balance T/T before shipment.

| Application: | Fastener, Auto and Motorcycle Accessory, Hardware Tool, Machinery Accessory, Aerospace/ Marine/Automotive/Medical Equipments |

|---|---|

| Standard: | GB, EN, China GB Code |

| Surface Treatment: | Anodizing,Polishing,Brushing, Plating, Oxide Black |

| Production Type: | Mass Production |

| Machining Method: | CNC Machining, Turning, Milling, Forging |

| Material: | Nylon, Steel, Plastic, Brass, Alloy, Copper, Aluminum, Iron, Customized |

| Samples: |

US$ 0.8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How does the size of a sun gear affect the gear ratio in planetary systems?

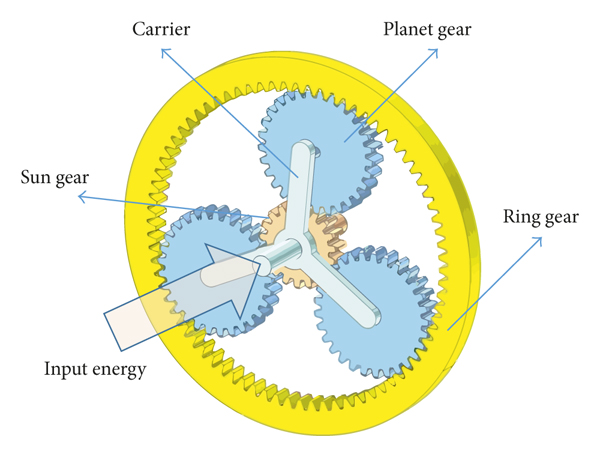

The size of the sun gear plays a significant role in determining the gear ratio in planetary gear systems. The gear ratio determines the relationship between the input speed and torque and the output speed and torque in the system. Here’s an explanation of how the size of the sun gear affects the gear ratio in planetary systems:

- Direct Proportion:

In a planetary gear system, the gear ratio is influenced by the relative sizes of the sun gear, planet gears, and ring gear. The gear ratio is typically expressed as the ratio of the output speed to the input speed or the ratio of the output torque to the input torque.

When considering the size of the sun gear, it is important to understand that the gear ratio is inversely proportional to the size of the sun gear. In other words, as the size of the sun gear increases, the gear ratio decreases, and vice versa.

- Power Distribution:

The size of the sun gear affects the power distribution within the planetary system. As the sun gear rotates, it engages with the planet gears, which, in turn, mesh with the ring gear. The interaction between these gears determines the gear ratio.

A larger sun gear allows for a higher number of teeth on the sun gear itself as well as on the planet gears. This means that each rotation of the sun gear will result in a smaller rotation of the planet gears and the ring gear. Consequently, a larger sun gear leads to a lower gear ratio, reducing the output speed and increasing the output torque.

- Torque Amplification:

Another factor influenced by the size of the sun gear is torque amplification. In planetary gear systems, the sun gear’s size affects the torque multiplication or reduction capabilities of the system.

With a larger sun gear, the system can provide higher torque output for a given input torque, resulting in torque amplification. This can be advantageous in applications where increased torque is required, such as during vehicle acceleration or heavy load conditions.

Conversely, a smaller sun gear reduces the torque output of the system, resulting in torque reduction. This can be useful in situations where a lower torque output is desired, such as when precise control is required or when operating in low-torque applications.

- Overall Gear Ratio Range:

The size of the sun gear also affects the overall gear ratio range that can be achieved in a planetary system. By varying the size of the sun gear relative to the other gears, different gear ratios can be achieved, allowing for a wider range of output speeds and torques.

For example, if a system requires a higher gear ratio range, a larger sun gear can be used in combination with appropriately sized planet gears and a ring gear. Conversely, if a lower gear ratio range is desired, a smaller sun gear can be employed.

It’s important to note that the size of the sun gear alone does not determine the gear ratio. The gear ratio is influenced by the combination of the sizes of all the gears within the planetary system.

In summary, the size of the sun gear in a planetary gear system has a direct impact on the gear ratio, power distribution, torque amplification, and overall gear ratio range. A larger sun gear results in a lower gear ratio, while a smaller sun gear leads to a higher gear ratio. The size of the sun gear, along with the sizes of the other gears, determines the performance characteristics of the planetary system.

Can you explain the function of a sun gear in automatic transmissions?

The sun gear plays a crucial role in the operation of automatic transmissions. It is an essential component within the planetary gear set, which is responsible for transmitting power and controlling gear ratios in automatic transmissions. Here’s an explanation of the function of a sun gear in automatic transmissions:

- Power Input:

The sun gear serves as one of the primary power input sources in an automatic transmission. It connects to the torque converter, which is a fluid coupling that transfers engine power to the transmission. The rotation of the sun gear receives torque from the engine and acts as the initial input for the gear set.

- Gear Ratio Control:

The sun gear, along with other gears in the planetary gear set, allows for the control of gear ratios in an automatic transmission. By varying the engagement and rotation of the sun gear, different gear ratios can be achieved, providing the desired combination of torque multiplication and speed reduction or increase.

The gear ratio control is achieved through the interaction between the sun gear, planet gears, and ring gear. The sun gear is connected to the planet gears, which in turn mesh with the ring gear. The arrangement and rotation of these gears determine the gear ratio and, consequently, the output speed and torque of the transmission.

- Forward and Reverse Operation:

The sun gear’s function also extends to enabling both forward and reverse operation in automatic transmissions. By controlling the engagement of the sun gear with other gears in the planetary set, the transmission can switch between forward and reverse directions.

In the forward operation, the sun gear engages with the planet gears and the ring gear, transmitting power from the input shaft to the output shaft with a specific gear ratio. In the reverse operation, the sun gear engages with a different set of gears, causing the rotation of the output shaft to reverse its direction.

- Torque Multiplication:

Another important function of the sun gear is torque multiplication. By utilizing the planetary gear set arrangement, the sun gear can multiply or reduce torque depending on the gear ratio configuration. This torque multiplication capability allows the transmission to provide higher torque output when needed, such as during acceleration or climbing steep gradients.

- Gear Shifts:

The sun gear’s function also contributes to smooth and efficient gear shifts in automatic transmissions. As gear shifts occur, the transmission control unit adjusts the engagement of the sun gear, planet gears, and ring gear to achieve the desired gear ratio for the target speed and load conditions.

During gear shifts, the engagement of clutches or bands controlled by the transmission control unit ensures that the sun gear rotates with the desired set of gears, allowing for seamless transitions between different gear ratios. This coordinated operation of the sun gear and other gears facilitates smooth acceleration and deceleration without excessively straining the transmission components.

In summary, the sun gear in automatic transmissions serves multiple functions, including power input from the torque converter, gear ratio control through its engagement with other gears, enabling forward and reverse operation, torque multiplication for increased output, and contributing to smooth gear shifts. These functions collectively allow automatic transmissions to provide efficient power transfer, dynamic gear ratios, and smooth operation in various driving conditions.

What are the advantages of using a sun gear in a planetary gear set?

The utilization of a sun gear in a planetary gear set offers several advantages, contributing to the popularity and wide range of applications of this gear configuration. Understanding the specific benefits of using a sun gear helps in appreciating its advantages in mechanical systems. Here’s an explanation of the advantages of using a sun gear in a planetary gear set:

- Torque Amplification: One of the significant advantages of a planetary gear set with a sun gear is its ability to amplify torque. By arranging the sun gear, planet gears, and an outer ring gear, torque can be multiplied or reduced depending on the specific gear ratio configuration. This torque amplification feature is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Compact Design: Planetary gear sets with a sun gear often enable a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions, where a smaller and lighter gear system is desirable.

- High Gear Ratios: The presence of a sun gear in a planetary gear set facilitates the attainment of high gear ratios. By manipulating the sizes and arrangements of the sun gear, planet gears, and ring gear, a wide range of gear ratios can be achieved. This flexibility in gear ratio control enables planetary gear sets to provide various output speeds and torque levels, allowing for customization based on the specific requirements of the mechanical system.

- Load Distribution: The sun gear’s engagement with multiple planet gears in a planetary gear set allows for load distribution among the gears. This distributed load-sharing characteristic helps in reducing the load on individual gears, resulting in improved reliability and longevity of the gear system. It also enables efficient power distribution and helps prevent excessive wear and stress on any single gear within the system.

- Directional Control: Planetary gear sets with a sun gear provide versatile directional control. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control feature adds flexibility to mechanical systems, allowing for a wide range of applications that require bidirectional power transmission.

- Multiple Output Shafts: Another advantage of using a sun gear in a planetary gear set is the possibility of having multiple output shafts. By incorporating additional planet gears and output shafts, a planetary gear set with a sun gear can deliver power to multiple outputs simultaneously. This feature is beneficial in applications that require power distribution to multiple subsystems or components within a complex mechanical system.

In summary, the advantages of using a sun gear in a planetary gear set include torque amplification, compact design, high gear ratios, load distribution, directional control, and the potential for multiple output shafts. These advantages make planetary gear sets with a sun gear well-suited for a wide range of applications, including automotive, aerospace, machinery, robotics, and more.

editor by CX 2023-11-03