Product Description

Customized Wheel Transmission Starter Shaft Spline Pinion Planetary Sun Drive Spur Gear

Product Description

|

Material |

S45C steel, Stainless steel 304, Plastic, Brass, 42CrMo,20CrMnTi and so on |

|||

|

Heat treatment |

Hardening and Tempering, High Frequency Quenching,Carburizing etc |

|||

|

Surface treatment |

Blacking, Polishing, Anodization, Chrome Plating, Zinc Plating, Nickel Plating |

|||

|

Application |

Precision cutting machines. Lathes. Milling machines. Grinders. Automated mechanical systems. Automated warehousing systems. |

|||

|

Machining process: |

Hobbing, Milling, Drilling, Shaving, Grinding |

|||

1. Type: spur gear, helical gear, bevel gear, worm gear, ring gear etc.

2. Material: carbon steel, alloy steel, stainless steel, nylon, POM , plastic

3. Treatment: teeth hardened, zinc, quenching, black oxide, color zinc

4. OEM & Standard:Standard size according to the catalog.OEM size, hub, hole, keyway and

set screw, all can produce according to your drawing.

5. Gear drive advantages:High transmission accuracy, high transmission efficiency, reliable work

and long service life.

Our Service:

1. Competitive price

2. High quality products

3. OEM service

4. 24 hours online service

5. Professional technical service

6. Sample available

1. We are a professional manufacturer specializing in manufacturing various metal parts, including

CNC precision automatic lathe machined parts, automatic lathe parts, milling machined parts, wire

cutting machined parts etc.

2.With experienced technical engineers and modern inspection equipment, our factory can help you to

lower cost at the moment of worldwide financial crisis.

3.We are committed to focusing on the client’s demand and satisfaction, and to providing high quality

products at competitive prices according to your drawings or samples. Special parts for your special

needs!

4.Our strong R&D and QC department can control the products to meet your strict requirment, 100%

inspection on critical dimensions with high accuracy +/-0.01-0.005mm.

5.We are committed to focusing on the client’s demand and satisfaction, and to providing high quality

products at competitive prices according to your drawings or samples. Special parts for your special

needs!

6.Although the business has become more difficult since competition increased, our products have

sold well in recent years. As a matter of fact, our parts are being exported to more than 10 countries

and regions. And they’re always received favourably.

Our Main Product:

1. Gear and Rack

2. Ball Screw and Nut

3. Linear Xihu (West Lake) Dis. and Block

4. Sprocket and Roller Chain

5. Timing Pulley and Timing Belt

Application

Gear can be used on many machines,like lathe machine, cutting machine, cnc machine and engraving

machine etc; It can also be used in many fields, machinery, construction, building, manufacturing,

industrial etc.

Package

Usually we wrap the gears with bubble wrap, then put the gears in a carton, and finally seal the

carton tightly.We can also make the package according to customers’ demands.

FAQs

Q: Are you factory or trading company?

A:Truly we are a factory over 15 years. We located in HangZhou City, ZheJiang Province, near

HangZhou port.

Q: What is your production range?

A: Gears, impellers, shaft; shaft couplings; end cover; cnc machining parts,etc.

Q: How long can I get some samples for checking and what about the price?

A: Normaly samples will be done within 3-5 days.

The sample cost depends on the information (size, material, finish, etc.).

We will return the sample cost when you place order.

Q:How is the warranty of the products quality control?

A:We hold the tightend quality controlling from very begining to the end and aim at 100% error free.

Q:How to get an accurate quotation?

A:If you are interested in our products, please provide us with below information:

If there is something you are demanding or interested, please feel free to contact with

us, we will feedback within 12 hours.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Application: | Motor, Electric Cars, Motorcycle, Machinery, Marine, Agricultural Machinery, Car |

|---|---|

| Hardness: | Soft Tooth Surface |

| Gear Position: | External Gear |

| Samples: |

US$ 15/Piece

1 Piece(Min.Order) | Order Sample Samples produced according to customer′s drawing

|

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

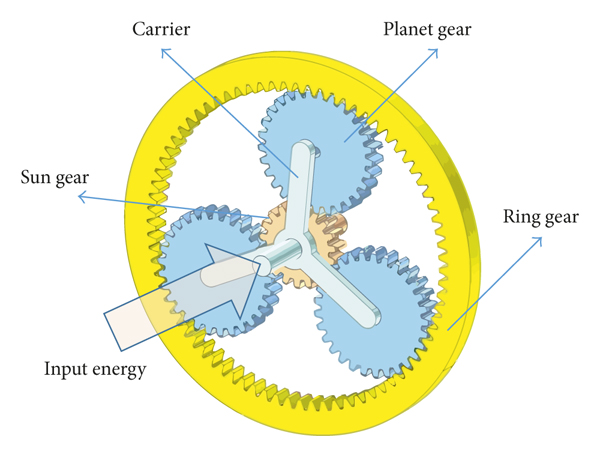

How does the size of a sun gear affect the gear ratio in planetary systems?

The size of the sun gear plays a significant role in determining the gear ratio in planetary gear systems. The gear ratio determines the relationship between the input speed and torque and the output speed and torque in the system. Here’s an explanation of how the size of the sun gear affects the gear ratio in planetary systems:

- Direct Proportion:

In a planetary gear system, the gear ratio is influenced by the relative sizes of the sun gear, planet gears, and ring gear. The gear ratio is typically expressed as the ratio of the output speed to the input speed or the ratio of the output torque to the input torque.

When considering the size of the sun gear, it is important to understand that the gear ratio is inversely proportional to the size of the sun gear. In other words, as the size of the sun gear increases, the gear ratio decreases, and vice versa.

- Power Distribution:

The size of the sun gear affects the power distribution within the planetary system. As the sun gear rotates, it engages with the planet gears, which, in turn, mesh with the ring gear. The interaction between these gears determines the gear ratio.

A larger sun gear allows for a higher number of teeth on the sun gear itself as well as on the planet gears. This means that each rotation of the sun gear will result in a smaller rotation of the planet gears and the ring gear. Consequently, a larger sun gear leads to a lower gear ratio, reducing the output speed and increasing the output torque.

- Torque Amplification:

Another factor influenced by the size of the sun gear is torque amplification. In planetary gear systems, the sun gear’s size affects the torque multiplication or reduction capabilities of the system.

With a larger sun gear, the system can provide higher torque output for a given input torque, resulting in torque amplification. This can be advantageous in applications where increased torque is required, such as during vehicle acceleration or heavy load conditions.

Conversely, a smaller sun gear reduces the torque output of the system, resulting in torque reduction. This can be useful in situations where a lower torque output is desired, such as when precise control is required or when operating in low-torque applications.

- Overall Gear Ratio Range:

The size of the sun gear also affects the overall gear ratio range that can be achieved in a planetary system. By varying the size of the sun gear relative to the other gears, different gear ratios can be achieved, allowing for a wider range of output speeds and torques.

For example, if a system requires a higher gear ratio range, a larger sun gear can be used in combination with appropriately sized planet gears and a ring gear. Conversely, if a lower gear ratio range is desired, a smaller sun gear can be employed.

It’s important to note that the size of the sun gear alone does not determine the gear ratio. The gear ratio is influenced by the combination of the sizes of all the gears within the planetary system.

In summary, the size of the sun gear in a planetary gear system has a direct impact on the gear ratio, power distribution, torque amplification, and overall gear ratio range. A larger sun gear results in a lower gear ratio, while a smaller sun gear leads to a higher gear ratio. The size of the sun gear, along with the sizes of the other gears, determines the performance characteristics of the planetary system.

What is the role of a sun gear in the operation of a differential gear system?

The sun gear plays a vital role in the operation of a differential gear system, which is commonly used in vehicles to distribute power between the wheels while allowing them to rotate at different speeds. The sun gear, along with other gears in the differential, contributes to the smooth and efficient operation of the system. Here’s an explanation of the role of a sun gear in the operation of a differential gear system:

- Power Input:

The sun gear serves as the input for the differential gear system. It receives torque from the driveshaft or propeller shaft, which transfers power from the engine or transmission to the differential. The rotation of the sun gear initiates the power flow within the differential assembly.

- Speed Differentiation:

The primary function of the differential gear system is to allow the wheels to rotate at different speeds while distributing power between them. The sun gear, along with the other gears in the differential, enables this speed differentiation.

As the sun gear rotates, it meshes with the planet gears, which are arranged around it. The planet gears, in turn, engage with the ring gear, which is connected to the axle shafts leading to the wheels. The interaction between the sun gear, planet gears, and ring gear allows the differential to accommodate different rotational speeds of the wheels.

- Distribution of Torque:

Another critical role of the sun gear is to distribute torque between the wheels in a differential system. The torque input from the sun gear is transmitted to the planet gears, which then transfer the torque to the ring gear and, subsequently, to the axle shafts and wheels.

As the differential operates, it adjusts the distribution of torque based on the traction and resistance encountered by each wheel. If one wheel experiences less resistance or has more traction than the other, the differential will allocate more torque to that wheel. This torque distribution helps optimize power delivery, improve traction, and enhance vehicle stability during cornering or uneven road conditions.

- Equal Torque Split (Open Differential):

In an open differential system, which is the most common type, the sun gear plays a role in equal torque split between the wheels under normal driving conditions. When both wheels have equal traction and resistance, the sun gear distributes torque equally to the planet gears, resulting in an equal torque split between the wheels.

However, in situations where one wheel loses traction or encounters less resistance, such as during wheel slip or when one wheel is on a slippery surface, the open differential will prioritize torque delivery to the wheel with less traction, potentially reducing overall traction and performance.

- Limited-Slip Differential:

In some differential systems, such as limited-slip differentials (LSDs), the sun gear’s role is modified to provide improved traction and torque distribution. LSDs use various mechanisms, such as clutch packs or viscous fluids, to limit the speed differentiation between the wheels and redirect torque to the wheel with more traction.

In LSDs, the sun gear’s engagement with the other gears is modified to allow for controlled torque transfer, enhancing traction and stability during challenging driving conditions.

In summary, the sun gear in a differential gear system serves as the power input and enables speed differentiation and torque distribution between the wheels. Its role is crucial for ensuring smooth power delivery, optimizing traction, and enhancing vehicle stability in various driving conditions.

What are the advantages of using a sun gear in a planetary gear set?

The utilization of a sun gear in a planetary gear set offers several advantages, contributing to the popularity and wide range of applications of this gear configuration. Understanding the specific benefits of using a sun gear helps in appreciating its advantages in mechanical systems. Here’s an explanation of the advantages of using a sun gear in a planetary gear set:

- Torque Amplification: One of the significant advantages of a planetary gear set with a sun gear is its ability to amplify torque. By arranging the sun gear, planet gears, and an outer ring gear, torque can be multiplied or reduced depending on the specific gear ratio configuration. This torque amplification feature is particularly useful in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Compact Design: Planetary gear sets with a sun gear often enable a more compact and space-efficient design. The central positioning of the sun gear, along with the arrangement of other gears, allows for a reduction in overall size while maintaining efficient power transmission. This compactness is advantageous in applications with limited space or weight restrictions, where a smaller and lighter gear system is desirable.

- High Gear Ratios: The presence of a sun gear in a planetary gear set facilitates the attainment of high gear ratios. By manipulating the sizes and arrangements of the sun gear, planet gears, and ring gear, a wide range of gear ratios can be achieved. This flexibility in gear ratio control enables planetary gear sets to provide various output speeds and torque levels, allowing for customization based on the specific requirements of the mechanical system.

- Load Distribution: The sun gear’s engagement with multiple planet gears in a planetary gear set allows for load distribution among the gears. This distributed load-sharing characteristic helps in reducing the load on individual gears, resulting in improved reliability and longevity of the gear system. It also enables efficient power distribution and helps prevent excessive wear and stress on any single gear within the system.

- Directional Control: Planetary gear sets with a sun gear provide versatile directional control. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control feature adds flexibility to mechanical systems, allowing for a wide range of applications that require bidirectional power transmission.

- Multiple Output Shafts: Another advantage of using a sun gear in a planetary gear set is the possibility of having multiple output shafts. By incorporating additional planet gears and output shafts, a planetary gear set with a sun gear can deliver power to multiple outputs simultaneously. This feature is beneficial in applications that require power distribution to multiple subsystems or components within a complex mechanical system.

In summary, the advantages of using a sun gear in a planetary gear set include torque amplification, compact design, high gear ratios, load distribution, directional control, and the potential for multiple output shafts. These advantages make planetary gear sets with a sun gear well-suited for a wide range of applications, including automotive, aerospace, machinery, robotics, and more.

editor by Dream 2024-04-23