Product Description

Product Description

We(HangZhou BST) export construction machinery parts, specializes in the manufacturing and supplying of Shantui, Cat and komat su parts for over 15 years. Our company has a complete range such as engine parts ,transmission parts,hydraulic parts, electrical parts,drive parts,undercarriage parts, filter. Models such as komats D60/80/155,PC2

175-15-42322

09232-5715

571-5715

175-15-41140

706-7L-01110

209-27-00160

209-27-71370

21n-27-31330

209-27-61360

198-09-31630

209-27-71521

21n-27-31310

21n-27-31110

209-27-71330 Spitter

209-27-71261

207-27-61230

20Y-27-21250

209-27-71480

20Y-27-21290

209-27-71141

209-27-71410

21n-27-31250

209-27-71390

21n-27-31260

208-27-61350

20y-27-21240

209-27-71350

20G-26-11240

209-27-71310

20Y-27-21280

21n-27-31120

21n-27-31210

21n-27-31221

21n-27-00150

21n-27-31120

21n-09-31120

209-38-73360

06030-06219

06030- 0571 4

04070-00140

209-38-73170

07002-22434

07030-03034

07005-03016

209-38-73130

209-38-73140

06000-23124

07000-15335

21n-26-31140

208-26-52263

208-26-61291

21n-26-31110

20Y-27-21250

208-26-63140

207-27-63210

207-27-63230

20y-27-13310

208-26-63131

207-26-61180

207-27-63250

20Y-27-11250

208-26-63110

208-26-61151

20Y-27-22210

| Part name | Part No. | Des |

| Shantui Alternator | 4060811 | Shantui dozer parts |

| Shantui Alternator | 3016627 | Shantui dozer parts |

| Shantui Alternator | 4061007 | Shantui dozer parts |

| Shantui Alternator | VG1095094002 | Shantui dozer parts |

| Shantui Alternator | 6N9294/5S9088 | Shantui dozer parts |

| Shantui Alternator | D11-102-13 | Shantui dozer parts |

| Shantui Alternator | 13571500/4110000054053 | Shantui dozer parts |

| Shantui Alternator | 13571345/411000571005 | Shantui dozer parts |

| Alternator | JFZ279 | 28V 70A |

| Alternator | JFZ273 | 28V 70A |

| Alternator | JFZ276 | 28V 70A |

| Alternator | AVI136 series | 28V 70A |

| Alternator | AVI144 series | 28V 100A/14V 150A |

| Alternator | JFZ210/211 series | 28V 100A-110A |

| Alternator | 8LHA3096UC | 28V 110A |

| Alternator | 8LHA3040UC | 28V 120A |

| Alternator | 8SC3141VC series | 28V 140A-150A |

| Alternator | AC172RA series | 28V 140A |

| Alternator | AVi168A series | 28V 150A |

| Alternator | AVi168W series | 28V 150A |

| Alternator | AVi168F3001 | 28V 150A |

| Alternator | 8SC3239VC series | 28V 150A |

| Alternator | 8SC3238VC series | 28V 150A |

| Alternator | 8SC3110VC series | 28V 150A |

| Alternator | AVi147 series | 28V 120A |

| Alternator | AVi147 series | 28V 120A |

| Alternator | AVE2119-E | 28V 110A |

| Alternator | AViC2002C | 28V 70A |

| AOBO series | ||

| Alternator | JFZ2922 | 28V 55A |

| Alternator | JFZ2200C | 28V 70A |

| Alternator | JFZ2971A | 28V 75A |

| Alternator | JFZ2971B | 28V 75A |

| Alternator | JFZ2971D | 28V 75A |

| Alternator | JFZ2150 | 28V 150A |

| Alternator | HOWO | 28V 80A |

| Alternator | HOWO3000 | 28V 80A |

| series | ||

| Alternator | CA1666IR | 28V 80A |

| Alternator | CA1693IR | 28V 110A |

| Alternator | CA1148IR | 28V 80A |

| Alternator | CA907IR | 28V 80A |

| Alternator | CA550IR | 28V 55A |

| Alternator | CA1593IR | 28V 80A |

| Alternator | CA1699IR | 28V 80A |

| Alternator | CA853IR | 28V 80A |

| Alternator | CA1236IR | 28V 140A |

| Alternator | CA1237IR | 28V 140A |

| Alternator | CA1853IR | 28V 80A |

| Alternator | CA1883IR | 28V 110A |

| DENSO series | ||

| Alternator | DENSO series | 28V 95A |

| Alternator | DENSO series | 14V 130A |

| Alternator | Delco 24SI series | 28V 70A |

FAQ

Q1:You are a trader or manufacturer .

We are a trader .

Q2: How about the payment terms ?

We usually accept T/T . Other terms also could be negotiated .

Q3: Warranty

3-6 months warranty. If any parts break during the warranty, Just offer us the proof . We’ll send you a new 1 !

Q5:If parts be lost during delivery , how solve ?

We’ll resend the parts free of charge .

| After-sales Service: | 1 Year |

|---|---|

| Warranty: | 1 Year |

| Type: | Crawler |

| Application: | Excavator |

| Certification: | ISO9001: 2000 |

| Condition: | New |

| Samples: |

US$ 10/Piece

1 Piece(Min.Order) | |

|---|

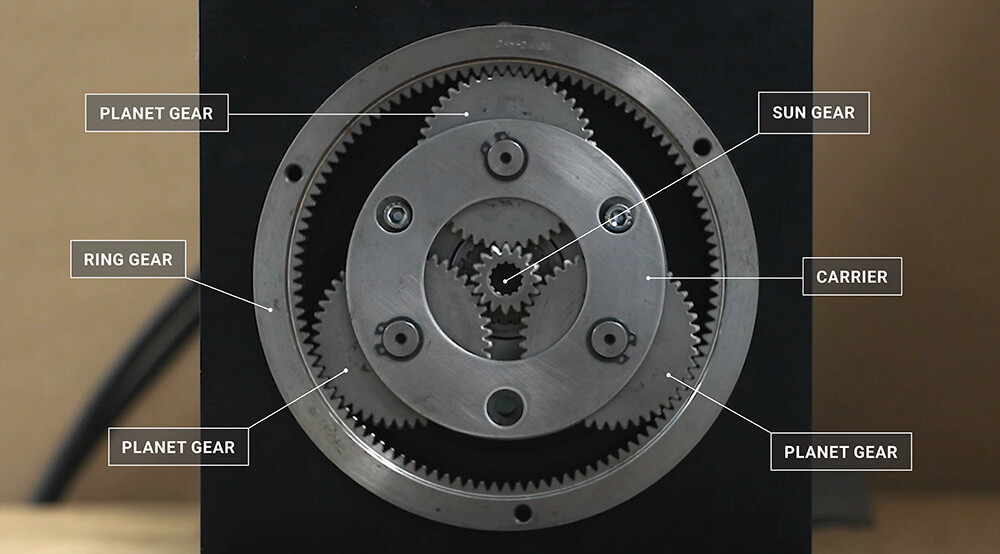

Can sun gears be used in automotive applications?

Sun gears are widely used in various automotive applications, playing crucial roles in different systems. Let’s explore the automotive applications where sun gears are commonly employed:

- Automatic Transmissions:

Sun gears are integral components of automatic transmissions in vehicles. Automatic transmissions use planetary gear systems, where the sun gear is one of the key elements. The interaction between the sun gear, planet gears, and ring gear allows for different gear ratios and smooth shifting between gears.

In automatic transmissions, the sun gear is driven by the engine’s input shaft and transmits power to the other gears. By controlling the engagement of various clutches and brakes within the transmission, the sun gear enables seamless gear changes, optimizing vehicle performance and fuel efficiency.

- Transfer Cases:

In four-wheel-drive and all-wheel-drive vehicles, transfer cases distribute power between the front and rear wheels. Sun gears are utilized in transfer cases to facilitate power transfer and gear reduction.

The sun gear, along with other gears and components, helps control the torque distribution and gear ratios between the front and rear axles. This allows vehicles to adapt to different driving conditions, such as slippery surfaces or off-road terrain, enhancing traction and stability.

- Starter Motors:

Sun gears are employed in starter motors, which are responsible for cranking the engine during startup. Starter motors use a gear reduction mechanism to convert the electric motor’s high-speed rotation into a higher torque output.

The sun gear, along with other gears like the planetary gears, enables the gear reduction necessary to generate sufficient torque to crank the engine. This gearing arrangement allows for efficient and reliable engine starting, even in challenging conditions.

- Power Seats and Windows:

Sun gears can also be found in power seat and power window mechanisms in vehicles. These systems use electric motors to adjust seat positions or operate windows.

The sun gear, along with other gears and mechanisms, converts the rotational motion of the electric motor into linear movement, enabling precise adjustments of seat positions or smooth operation of windows. The use of sun gears ensures reliable and efficient functionality of these systems.

- Other Automotive Systems:

Sun gears may also have applications in other automotive systems. For example, they can be found in power steering systems, where they contribute to the gear reduction and power transmission required for smooth steering operation.

Furthermore, sun gears can be utilized in various auxiliary systems, such as cooling fans, HVAC (heating, ventilation, and air conditioning) systems, and engine accessories. These applications leverage the sun gear’s ability to facilitate power transmission and gear reduction, enhancing the efficiency and performance of these systems.

In summary, sun gears are extensively used in automotive applications, including automatic transmissions, transfer cases, starter motors, power seats and windows, power steering systems, and auxiliary systems. Their presence in these systems enables crucial functions such as gear shifting, power distribution, gear reduction, and efficient power transmission. Sun gears contribute to the overall performance, reliability, and functionality of automotive systems, enhancing the driving experience and vehicle efficiency.

How do you calculate gear ratios involving a sun gear in planetary systems?

Calculating gear ratios in planetary systems involving a sun gear requires considering the number of teeth on the gears and their arrangement. Understanding the calculation process helps in determining the gear ratio and predicting the rotational relationship between the input and output gears. Here’s an explanation of how to calculate gear ratios involving a sun gear in planetary systems:

- Step 1: Identify the Gears: In a planetary system, identify the gears involved, namely the sun gear, planet gears, and ring gear. The sun gear is the gear at the center, surrounded by the planet gears, which in turn engage with the outer ring gear.

- Step 2: Count the Teeth: Count the number of teeth on each gear. The sun gear, planet gears, and ring gear all have a specific number of teeth. Let’s denote these as Ts (sun gear teeth), Tp (planet gear teeth), and Tr (ring gear teeth).

- Step 3: Determine the Gear Ratio: The gear ratio in a planetary system involving a sun gear is calculated using the following formula:

Gear Ratio = (Tp + Tr) / Ts

- Step 4: Interpret the Gear Ratio: The calculated gear ratio represents the rotational relationship between the input (sun gear) and output (ring gear) gears. For example, if the gear ratio is 2:1, it means that for every two revolutions of the sun gear, the ring gear completes one revolution in the opposite direction.

- Step 5: Adjust for Multiple Planet Gears or Fixed Components: In some cases, planetary systems may involve multiple planet gears or fixed components. The presence of multiple planet gears affects the gear ratio, and the inclusion of fixed components alters the gear engagement and behavior. These factors may require additional calculations or adjustments to accurately determine the gear ratio.

In summary, calculating gear ratios involving a sun gear in planetary systems necessitates identifying the gears, counting the teeth on each gear, and applying the appropriate formula. The resulting gear ratio provides insights into the rotational relationship between the sun gear and the ring gear. It’s important to consider any additional elements, such as multiple planet gears or fixed components, that may influence the gear ratio calculation.

How does a sun gear differ from other types of gears?

A sun gear has distinct characteristics that set it apart from other types of gears. While gears serve various purposes in mechanical systems, understanding the specific features of a sun gear can help differentiate it from other gear types. Here’s an explanation of how a sun gear differs from other gears:

- Central Position: Unlike many other gears that are located on the periphery of a gear system, a sun gear is positioned at the center of a planetary gear arrangement. It serves as a central driver within the system, transmitting torque to other gears.

- Engagement with Planet Gears: A defining feature of a sun gear is its engagement with multiple planet gears. These planet gears surround the sun gear and mesh with both the sun gear and an outer ring gear. The interaction between the sun gear and the planet gears allows for the transfer of torque and power distribution within the gear system.

- Gear System Configuration: Sun gears are commonly found in planetary gear systems, where they function as a central component. Planetary gear systems consist of a sun gear, planet gears, and an outer ring gear. The arrangement and interaction of these gears enable various gear ratios, torque multiplication, and directional control.

- Power Input: In a planetary gear system, the sun gear typically receives power input from an external source, such as an engine or motor. It serves as the primary driving element that initiates torque transmission and power distribution within the system.

- Role in Gear Ratio: The sun gear’s size, number of teeth, and its interaction with the planet gears and ring gear determine the overall gear ratio. By altering the sizes and arrangements of these gears, manufacturers can achieve different speed and torque combinations, providing versatility in gear system applications.

While a sun gear has its unique characteristics, it is essential to note that gears come in various types and configurations, each serving specific purposes in mechanical systems. Different types of gears include spur gears, helical gears, bevel gears, worm gears, and more. Each type has its own design, tooth profile, and applications, catering to different needs such as speed reduction, torque multiplication, directional control, or noise reduction.

In summary, a sun gear differentiates itself through its central positioning, engagement with planet gears, configuration in planetary gear systems, role as a power input element, and influence on gear ratio. Understanding these distinctions helps in recognizing the specific functions and applications of sun gears within mechanical systems.

editor by CX 2023-10-08