Product Description

CX120 CX130 CX210 CX240 CX330 CX360 Swing Motor Sun Gear 1st Gear Sun Swing Gear for CASE Excavator Spare Parts

Porduct Information

| Product | CX210B Swing Motor Sun Gear |

| Material | Alloy steel |

| Models | CA-T-303 SR CA-T320 EX200 EC200 DX200 |

| Warranty | 3 months |

| Condition | China Professional |

| MOQ | 1Piece |

| Payment | T/T,AlibabaTradeAssurance,Paypal,etc |

| DeliveryTime | Within 12days after receiving the payment |

| Packing | Standardexportingpackingorasrequired |

| Transport | Bysea/air/express(DHL/FEDEX/TNT/UPS/EMS/Cityline) |

Other CASE Model We can provide

| Case CX360B. CX210B. CX75SR. CX36B. CX75. CX80C. CX700B. CX130C. CX130. CX130B. CX160C. CX180C. CX210B-EM. CX210C-8. CX210C. CX220B. CX220C. CX240B. CX240C. CX260C. CX300B. CX300C. CX350C. CX380C. CX460. CX470B. CX490C. CX500C. CX500D. CX800B. CX800CME. WX148. WX168. WX188. WX218 |

Other related Part Number

| Item | Part Numer | Part Name |

| 1 | 332/H4301 | Valve |

| 2 | K1000697A | swing motor |

| 3 | 332/H3904 | Cover |

| 4 | 332/H3917 | Gear sun |

| 5 | 332/H3918 | Gear Ring |

| 6 | 332/H3920 | Disk |

| 7 | 332/H3923 | snap ring |

| 8 | 332/H3924 | Ring centering |

| 9 | 332/H3925 | Gear sun |

| 10 | 332/H3926 | Toothed Ring |

| 11 | 332/H3928 | Gear reduction |

| 12 | 332/H3930 | Gear Planetary |

| 13 | 332/H3932 | Travel Motor Ring |

| 14 | 332/H3933 | Hub Housing |

| 15 | 332/H3925 | Gear Sun |

| 16 | 05/903811 | TRAVEL final drive floating seal FITS |

| 17 | 332/H3935 | Travel Motor |

| 18 | 20/951587 | Cover Assembly |

| 19 | 20/951592 | Sun Shaft Gear |

| 20 | 20/951593 | planetary gear |

| 21 | 20/951594 | 2nd Planetary Gear |

| 22 | 20/951596 | Gear Planetary |

Related Excavator Hydraulic Pump We can Supply

| For Kobelco | main pump number | For Sumitomo | main pump number |

| SK60SR/70SR | K3SP36B-(Without gear pump) | SH130 | K3V63DTP-9N2B |

| SK60SR/70SR | K3SP36B-(Dual gear pump) | SH130-5 | K7V63DTP-9Y2C |

| SK135/130 | K3V63DTP-0E01/0E02 | SH200-1 | K3V112DT-9C12(12T) |

| SK135-8/140-8/130-8 | K7V63DTP-0E13 | SH200-1 | K3V112DT-9C12(14T) |

| SK200SR | K5V80DTP-0E02 | SH240-5/SH200A5 | K3V112DTP-9Y14 |

| SK200-8/210-8/250-8 | K3V112DTP-YT0K | SH200A3 | K3V112DTP-9N49 |

| SK230-6E | K3V112DTP-9TEL | SH290-5 | K5V140DTP-9Y15 |

| SK200-6(with aluminium base) | K3V112DTP-9TDL | SH300A3 | K5V140DTP-9N0A |

| SK200-6(iron base) | K3V112DT-9T1L | SH350-5/SH300-5/CX360 | K5V160DTP-9Y04 |

| SK200-10/250-10 | K7V125DTP-0E3K | SH350-5 (K3V180) | K5V160DTP180R-9Y04 |

| SK330-6E (D3V112) | K3V112DTP-9TBR | SH450-5 | K3V180DTP-9Y0A |

| SK330-6 (D3V112) | K3V112DTP-9TBS | ||

| SK350-8 | K5V140DTP-YT0K | ||

| SK330-6E(D5V140) | K5V140DTP-9TBR | ||

| SK330-6 (D5V140) | K5V140DTP-9TBS | ||

| SK350-10 | K7V140DTP-0E3K | ||

| SK450-6/-6E | K3V180DTH-9TOV | ||

| SK460-8 | K5V200DPH-YTOK | ||

| For Kato | main pump number | For XCM-G | main pump number |

| HD512 | K3V63DT-9N04 | XE150 | K3V63DT-9N4H/9N2H |

| HD700 HD820-1/2/3 | K3V112DT-9N1A(14T) | XE150 | K7V63DTP-9N0E |

| HD700 HD820-1/2/3 | K3V112DT-9N1A(12T) | XE195/210/215/230/240 | K3V112DT-9NC9 |

| HD700 HD820-1/2/3 | K3V112DT-9N1A(14T) | XE195/210/215/230/240 | K3V112DT-9ND9 |

| HD700 HD820-1/2/3 | K3V112DT-9N1A(12T) | XE335C | K3V140DT-9ND9 |

| HD820-R | K3V112DT-9N7A | XE370C2/C3 | K5V160DTH-9N3A/9N4A |

| HD1430 | K3V180DT-9N15 | XE450/470C3/490 | K5V200DTH-9NOH |

| HD2045 | K3V180DTH-9N2S | ||

| for Volvo | main pump number | For Doosan | main pump number |

| EC140 | K3V63DT-9NOT | DH150 | K5V80DTP-HNOV |

| EC145 | K5V80DT-9NOJ | DX150 | K3V63DT-9N0T |

| EC210/EC240/EC210B | K3V112DT-9N24 | DH80/R80 | AP2D36 |

| SE240-3/EC240B | K3V112DT-9N2A | DH120/S130/150-7 | K3V63DT-HNOV |

| EC210D | K3V112DT-1E05 | DH150 | K3V63DTP-HNOW |

| EC290 | K3V140DT-9N04 | DH225-7 | K3V112DT-HN0V |

| EC250D | K5V140DT-1E05 | DX225 | K3V112DTP-9N1T |

| EC300D | K5V160DT-1E05 | DH225-9(power takeoff) | K3V112DTP-HN2M |

| EC360()/EC380 | K3V180DT-9N56(gear pump) | DH225-9-E(power takeoff) | K3V112DTP-9N2M |

| EC360(new)/EC380 | K3V180DT-9N05(Without gear pump) | DX260(power takeoff) | K3V112DTP-9NM9 |

| EC360 | K3V180DTP-9N05 | DH258 | K3V112DTP-HN1F |

| EC380(new) | K3V180DT-9N5P | S290 | K3V140DT-HNOV |

| EC460 | K3V180DTH-9N2B | S300-7 | K5V140DTP-9N01 |

| EC460 | K5V200DTH-9N0B | DX300 | K5V140DTP-9N07 |

| EC480D(new) | K5V200DTP-9N8X | DH320 | K3V180DT-HN0P |

| EC480D | K5V200DTH-9N2Y | EC360 DH500 | K5V200DTP-9N05 |

| SY335 DH500 | K5V200DTH-DH500 | ||

| For HYUNDAI | main pump number | For San-y | main pump number |

| R130 | K5V80DTP-9N05/9N01 | SY75 | K3VL80B-10RSM-L11-TB110 |

| R140-7/170-7 | K5V80DTP-9C05 | SY75(Electronic control) | K3VL80/B-10RSM-L1/1-TB307 |

| R150 | K5V80DTP-9N0W | SY135/SY135-5/-8 | K7V63DTP-0E23 |

| R130/150/160 | K3V63DT-9N1S/9N01 | SY130 | K3V63DT-9N2H |

| R130/140-7 | K3V63DT-9COS | SY135 | K3V63DT-9POH |

| R215-7 | K3V112DT-9N3P | SY205/215(Negative control)CM | K3V112DTP-9TCM |

| R215-9 | K3V112DTP-9P12 | SY205/215(Positive control)8L | K3V112DTP-9T8L |

| R215-9T/R225-9T/275-9T | K3V112DTP-9N62 | SY205/215(six holes)0E | K3V112DTP-0E11 |

| R210-7/220-7/225-7 | K3V112DT-9C32 | SY245/265 | K7V125DTP-0E05/0E09 |

| R290-7 | K3V140DT-9C12 | SY235 | K5V140DTP-0E01 |

| R300-7/305LC-7 | K5V140DTP-9C12 | SY235 | K5V140DTP-9T1L |

| R320-3 | K3V180DT-9N69 | SY335 | K5V160DTP-9T06 |

| R320-7/335-7 | K3V180DT-9C69 | SY335 | K5V160DTH-9T06 |

| R350/360-3/R385-9T | K3V180DTH-9N1S/9N4S | SY335 | K5V200DTH-9N1H |

| R360-7/7A | K3V180DTH-9C0S | SY385 | K5V200DTH-0E30 |

| R375/360-7 | K3V180DTP-9COG | SY365 | K5V160DTH-0E60 |

| R375/360-7 | K3V180DTP-9COG | SY330/360 | K3V140DT-9TCM |

| R455 | K5V200DTH-9C0Z | SY285 | K3V140DT-9T1L |

| SY485 | K5V212DPH-OE81 | ||

| For Hitachi | main pump number | For Liugong | main pump number |

| ZX200 | HPV102 | LG908 | K3SP36C |

| ZX200-3 | HPV118 | LG915 | K3V63DT-9N2J |

| ZX330/350/360-1 | HPV145 | LG920/922/923/925 | K3V112DT-9N64 |

| ZX330-3 | HPV145 | LG230 | K3V112DT-2N59 |

| ZX470-3 | K5V200DPH-0E02 | LG | K3V112DTP-9NE4 |

| ZX450-1 | K5V200DPH-0E11 | LG925EII | K5V140DTP-9N25 |

| For Komats-u | main pump number | For Zoomlion | main pump number |

| PC200-7 | HPV95 | ZE150E | K7V63DTP-9N0E |

| PC200-8 | HPV95 | ZE205/210/230/260 | K3V112DT-9N94 |

| Ca-terpilla-r | main pump number | generic brand | main pump number |

| CA-T312B | K3V63DT-9N2D | Universal model | K3V63DT-9N00(14T) |

| CA-T312C | SBS80 | Universal model | K3V112DT-9N00(14T) |

| CA-T320C/320D | SBS120 |

Our Main Products

| If you have other breaker spare parts demand,such as Travel Motor,Travel Gearbox,Travel Device,Final Drive,Swing Motor,Swing Gearbox,Swing Motor Assy,Swing Device,Hydraulic Pump,Engine,Hydraulic Gear Pump,Piston Shoes,Cylnder Block,Valve Plate,Arm CYL’ Seal,Boom CYL’ Seal,Bucket CYL’ Seal, Bucket,Teeth,Track Roller,Top Roller,Spocket,Track Link,Monitor,Controller,etc,please click the below picture for more information,we believe we can save much of your timeand be your ONE STOP supplier. |

We could supply the following spare parts

| Engine Assembly | Final Drive Assy | HydraulicPump | Gear Pump |

| Swing Motor | TravelMotor | Fan Motor | Electrical Parts |

| SwingGearbox | Travel Gearbox | Relief Valve | Distribution Valve |

| Front Idler | Adjust Cylinder | Carrier Roller | Spocket |

| Track Roller | Track Shoe | Track Link | Excavator Track Assy |

| Teeth/Tooth | Adaptor/Teeth Seat | Muffler | Bucket |

Applicable To Excavator Model Number

| Komats*u | PC56-7 PC60-8 PC70-8 PC110-7 PC130-7 PC160-7 PC200-7 PC200-8 PC200LC-8 PC210-8 PC210LC-8 |

| PC220-8 PC240LC-8 HB205-1 HB215LC-1 | |

| PC270-7 PC300-7 PC360-7 PC400-8 PC450-8 OTHERS | |

| Kobelco | SK130-8 SK135-8 SK140-8 SK200-6 SK200-8 SK210-8 SK250-8 SK260LC-9 SK330-6 SK200-6E SK250-6E |

| SK230-6E SK330 SK350-6E SK350-8 SK55SR-5 SK55SRX SK60-C SK60-8 SK70SR-2 SK75-8 SK130 SK135SR-2 SK140LC SK140LC-8 SK210LC-8 SK250-8 | |

| SK260LC-8 SK270D SK330-8 SK350LC-8 SK380D SK460-8 SK480 SK480-8 SK495D SK850LC OTHERS | |

| Hyundai | R130-7 R140-7 R150 R150-9 R200-7 R210-5 R210-7 R215-7 R215-9 R220-5 R225-7 R225-9 R225-9T |

| R265-9T R265-9 R290-7 R300-5 R305-7 R335 R335-7 R335-9 R360 R370 R375-7 R385 R455 R460 R465 R485 R505 | |

| Doosan | DH85 DH150W DH215-9 DH220-5 DH220-7 DH225-7 DH225-9 DH258-7 DH300-V DH360 DH300LC-7 DX260 DH370 DH420 DH55 DX60 DH60-7 DX75 DX80 |

| DX120 DX150LC DH150LC-7 DH215-9 DH215-9E DH220LC-9E DH225LC-9 DX260LC DX300LC DH300LC-7 DX345LC DH370LC-9 DX380LC DX420LC | |

| DH420LC-7 DX500LC DH500LC-7 DX700LC | |

| Kobuto | KX71-2 KX71-3 KX61-2 KX71 KX61 KX91.3 |

| Hitachi | EX35 ZX30CLR EX30.2 |

| Daewood | 130 150 |

| Sumitomo | SH200 SH200-1 SH 200-2 SH200-Z3 SH200-A3 SH240-A5 SH350-3 SH350 SH360 SH365 |

| Jacob | JCB200 JCB210 JCB220 JCB240 JCB802.7 |

| CASE | CX210B CX240B CK25 CX350 CX365 CX360 |

| Yanmar | B25 B25V B37V VIQ30 B22 |

| SAN*Y | SY65 SY75 SY135 SY215 SY215-8 SY205-8 SY215-8S SY205-9 SY215-9 SY235-8 SY245 SY305 SY285 |

| SY335 SY365 SY375 SY385 SY465 SY700 SY485H | |

| XCM*G | XCMG160D XCMG200DA XCMG250 XCMG260 XCMG370 XCMG470 |

Our Company–Xihu (West Lake) Dis.an Machinery/KoKo Shop

Koko Shop Machine Co.,Ltd(EBSeals) is aprofessional supplier for hydraulic breaker parts and excavator parts and OEM hydraulic seals manufacturer. We specialize in completed seal kits and separate seals for hydraulic breaker and excavator more than Ten years in HangZhou,China.Koko Shop supplyal most all brands breakers’parts like Seal kits,Diaphragm,Piston,Chisel,Wear Bush upper and lower,Rod Pin,Through Bolts,Side Bolts,Control Valve,Front Head,Cylinder,Accumulator,N2 GasCharging Kit,etc.We insiston high quality partswith genuineand OEM CHINAMFG replacement parts.

Our Advantages

| 1 Excavator spare parts in full scale are available; |

| 2 100% quality assurance,developand manufacture follow original ones; |

| 3 Quickre sponse within 24 hours; |

| 4 Small order allowed; |

| 5 Reasonable stock and timely delivery; |

| 6 Original packing,neutral packing or customized packing; |

| 7 Positive customer feedback froma broad market; |

| 8 Excellent Aftersales service. |

FAQ

| Q1. How many days for the delivery time ? |

| It is about 1-7 working days after the order confirmation. |

| Q2. What kind of payments you accept? |

| Now we accept T/T,L/C or Western Union,other terms also could be negotiated,Recommended Trade Assurance to guarantee buyer’s property. |

| Q3. Are you able to manufacturing products according to customer’s design? |

| Sure,we have made many special orders from oversea for 10 years since 2571. So we have enough ability to deal with any cases. OEM certificate is available to provided. |

| Q4. What’s your advantages in the machinery manufacturing industry? |

| Fast delivery time,High quality products,Best customer service,Adopting the latest production technology. |

| Q5. Which countries have you been exported recently? |

| Canada,Australia,Peru,Egypt,Brazil,Mexico,South Africa,etc. |

| Q6. Are you sure that your product will suit for our excavator? |

| We have different brand hydraulic breakers. Show me your model number,and we can give you best match products. |

| Q7. How about the packing of the goods? |

| Standard export package,wood cases,or as customers’ demands. |

| After-sales Service: | Online Support |

|---|---|

| Warranty: | 3 Months |

| Type: | Excavator Spare Parts |

| Application: | Excavator |

| Certification: | CE, ISO9001: 2000 |

| Condition: | New |

| Customization: |

Available

| Customized Request |

|---|

Can sun gears be used in renewable energy systems?

Sun gears can indeed be used in renewable energy systems, particularly in applications that involve the conversion and transmission of mechanical power. Let’s explore how sun gears can be utilized in different types of renewable energy systems:

- Wind Turbines:

In wind turbines, sun gears can be employed as part of the gearbox mechanism. The gearbox is responsible for increasing the rotational speed of the wind turbine’s rotor to generate electricity efficiently. Sun gears, along with other gears such as planet gears and ring gears, can be used to achieve the desired gear ratios and torque amplification. By leveraging sun gears, wind turbines can convert the relatively low rotational speed of the rotor into the higher rotational speed required by the generator, which produces electricity.

- Solar Tracking Systems:

Sun gears can also play a role in solar tracking systems, which are used to maximize the energy generation of solar panels by orienting them towards the sun throughout the day. These systems often utilize gears to control the movement of the solar panels. Sun gears can be incorporated into the gear mechanism to enable precise tracking and adjustment of the solar panels’ position, ensuring optimal sunlight exposure and energy capture.

- Hydroelectric Power Plants:

In hydroelectric power plants, sun gears can be employed in the turbine and generator systems. These systems use the force of flowing or falling water to drive turbines, which, in turn, generate electricity. Sun gears can be part of the turbine’s gearbox, enabling the efficient conversion of the low-speed rotation of the turbine into the high-speed rotation required by the generator. By utilizing sun gears, hydroelectric power plants can enhance the power generation capabilities of the turbines.

- Wave and Tidal Energy Converters:

Wave and tidal energy converters harness the power of ocean waves and tides to generate electricity. Sun gears can be utilized in the transmission systems of these converters. They can help convert the slow, oscillating motion of the waves or tides into a higher rotational speed suitable for driving generators. By incorporating sun gears, these converters can optimize the energy extraction process and improve the efficiency of power generation.

- Geothermal Power Plants:

In geothermal power plants, sun gears can be used in various components of the energy conversion process. Geothermal power plants extract heat from the Earth’s interior to generate electricity. Sun gears can be employed in systems such as turbines and generators, where they facilitate the conversion of thermal energy into mechanical and electrical energy. By utilizing sun gears, geothermal power plants can enhance the efficiency and performance of the energy conversion systems.

In summary, sun gears can find applications in renewable energy systems such as wind turbines, solar tracking systems, hydroelectric power plants, wave and tidal energy converters, and geothermal power plants. By leveraging the functionality of sun gears, these systems can optimize power generation, increase efficiency, and contribute to the sustainable utilization of renewable energy sources.

What are the considerations for lubrication and maintenance of sun gears?

Proper lubrication and maintenance of sun gears are crucial for ensuring their optimal performance, longevity, and reliability. Sun gears, like other mechanical components, require appropriate lubrication to minimize friction, reduce wear, and prevent damage. Here are some considerations for lubrication and maintenance of sun gears:

- Lubrication:

Effective lubrication is essential for sun gears to operate smoothly and efficiently. Consider the following aspects:

- Lubricant Selection: Choose a lubricant that is specifically designed for gear applications. The lubricant should have the necessary viscosity, additives, and thermal stability to provide adequate lubrication and protection to the sun gears under the operating conditions.

- Proper Lubricant Application: Ensure that the lubricant is applied correctly to the sun gears. This can involve methods such as oil baths, oil mist systems, or grease application, depending on the specific gear system and its requirements. Follow the manufacturer’s guidelines or consult with lubrication experts for the appropriate lubrication technique.

- Regular Lubricant Inspection: Monitor the lubricant condition regularly to ensure its effectiveness and to detect any signs of contamination, degradation, or insufficient lubrication. Perform oil analysis or visual inspections as recommended by lubrication experts or equipment manufacturers.

- Maintenance:

Proper maintenance practices help keep sun gears in optimal working condition and extend their service life. Consider the following maintenance considerations:

- Regular Inspections: Conduct routine inspections of the sun gears to check for any signs of wear, damage, misalignment, or abnormal operating conditions. Inspections can help identify potential issues early, allowing for timely maintenance or repairs.

- Torque and Load Monitoring: Keep track of the torque and load applied to the sun gears. Ensure that the gear system is not subjected to excessive loads or overloading, as this can lead to premature wear and failure. Use appropriate monitoring techniques, such as load sensors or torque meters, to ensure the gear system operates within its designed limits.

- Alignment and Gear Meshing: Ensure proper alignment and gear meshing between the sun gear, planet gears, and ring gear. Misalignment or improper gear engagement can cause excessive wear and damage to the gear system. Regularly check and adjust the gear alignment as needed.

- Proactive Repairs and Replacements: If any issues, such as worn teeth, damaged gear components, or abnormal vibrations, are detected during inspections or monitoring, take proactive measures to repair or replace the affected parts. Timely repairs can prevent further damage and improve the overall performance and reliability of the sun gears.

- Operating Conditions: Consider the operating conditions of the gear system, such as temperature, humidity, and environmental factors. Ensure that the sun gears are protected from excessive heat, moisture, contaminants, and corrosive substances that can adversely affect their performance and durability.

In summary, proper lubrication and maintenance of sun gears are critical for their optimal performance and longevity. Considerations include selecting the right lubricant, applying it correctly, inspecting the lubricant regularly, conducting routine inspections, monitoring torque and load, ensuring proper alignment and gear meshing, performing proactive repairs and replacements, and considering the operating conditions. Adhering to these considerations helps ensure reliable and efficient operation of sun gears in various mechanical systems.

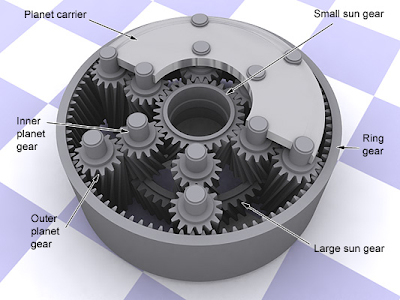

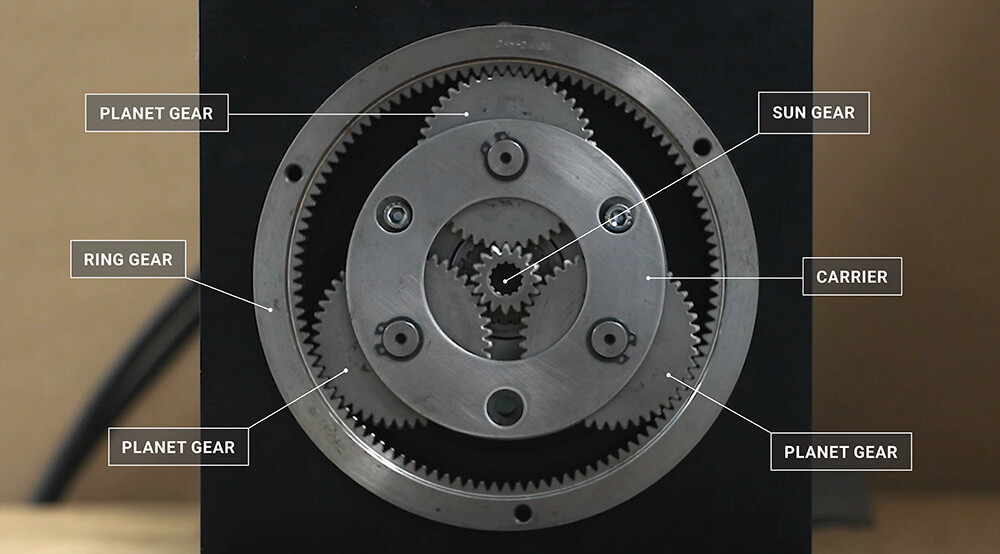

Can you explain the role of a sun gear in planetary gear systems?

The sun gear plays a crucial role in planetary gear systems, contributing to their unique functionality and versatility. Understanding the specific role of the sun gear within these systems helps in comprehending their overall operation. Here’s an explanation of the role of a sun gear in planetary gear systems:

- Power Input: The sun gear serves as the primary power input element in a planetary gear system. It receives rotational motion and torque from an external source, such as an engine or motor. This power input is transmitted to other gears within the system.

- Engagement with Planet Gears: One of the distinctive features of a planetary gear system is the interaction between the sun gear and multiple planet gears. The planet gears are smaller gears that surround the sun gear and mesh with both the sun gear and an outer ring gear. This engagement allows for the transfer of torque and motion between the gears.

- Power Distribution: As the sun gear rotates, it transmits torque to the planet gears through their meshing teeth. The planet gears, in turn, transfer the torque to the outer ring gear. This power distribution mechanism enables the sharing of torque among multiple gears within the system, allowing for load distribution and efficient power transmission.

- Gear Ratio Control: By changing the arrangement and sizes of the sun gear, planet gears, and ring gear, planetary gear systems can achieve different gear ratios. The number of teeth on the sun gear, planet gears, and ring gear, as well as their relative sizes, determine the gear ratio. This flexibility in gear ratio control enables planetary gear systems to provide various output speeds and torque levels, catering to different operational requirements.

- Torque Amplification: A key advantage of planetary gear systems is their ability to amplify torque. By employing a combination of the sun gear, planet gears, and ring gear, torque can be multiplied or reduced depending on the gear ratio configuration. This torque amplification feature is beneficial in applications where high torque output is required, such as automotive transmissions and heavy machinery.

- Directional Control: Another notable aspect of planetary gear systems is their directional control capability. By fixing or holding the sun gear while the ring gear or planet carrier is driven, the gear system can achieve different output directions, such as forward or reverse rotation. This directional control adds versatility to gear systems, enabling them to be used in various mechanical applications.

In summary, the sun gear in planetary gear systems serves as the power input element, engages with planet gears, distributes torque, controls gear ratios, provides torque amplification, and enables directional control. Its role is essential in achieving efficient power transmission, versatile gear ratios, and adaptable functionality in a wide range of mechanical applications.

editor by CX 2023-10-16