Description

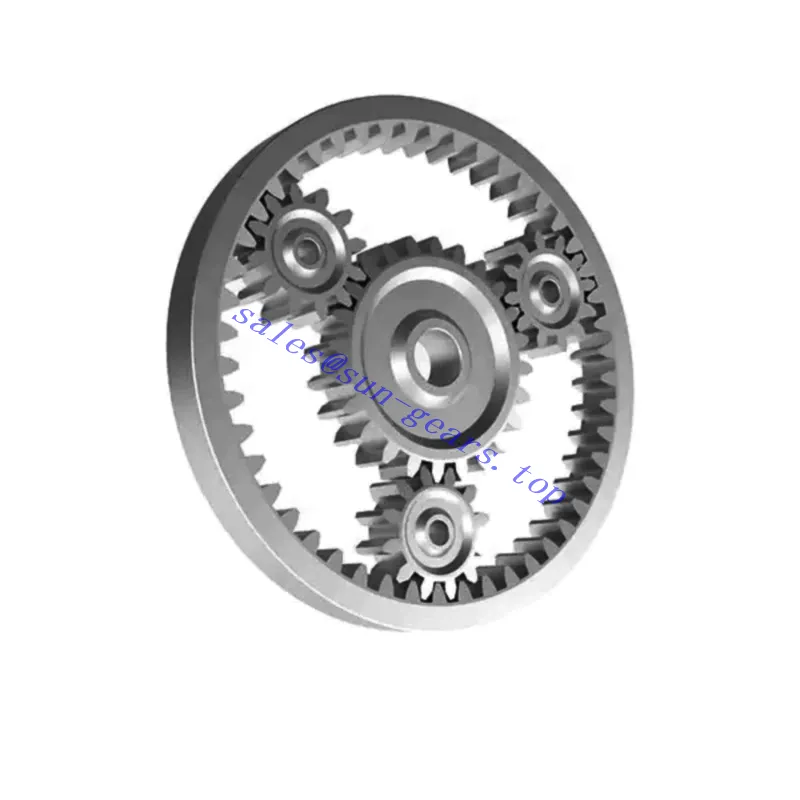

Planetary Gear

| Materials | Normal Plastic:PP,PE,EVA,PS; Engineering Plastic:PA,PA6,PA66,PC+ABS,PA+60%GF,PC,ABS,POM,PBT,TPU,TUR; High Engineering Plastic:PEEK,PPS,PPO,PEI,PES,PLA,LCP,Antistatic Plastic,Etc; |

| Machining Equipment | CNC,EDM,ArgieCharmilles,Milling Machine,3D CMM,Projector,HG,

Injection Machine; |

| Surface Treatment | Polishing/Smooth,Texture/Frosted,Printing,Painting,Plating; |

| Processing Craft | Milling,Griding,Drilling,Engraving,etc; |

| Mold Material | P20,718H,NAK80,H13,2738,S136,SKD61,Etc; |

| Mold Life | 100,000-5,000,000 Shots; |

| Application | All kinds of plastic injection parts being used in a variety of applicationgs including home use and industrial ues; |

| Mould Base | LKM,FUTA,HASCO,DME,Etc,Or as per customer’s requirement; |

| Testing Facility | Coordinate Measuring Machine,Projector,Roughness Tester,Hardness Tester,Concentricity Tester,Tool Microscope,Digimatic Micrometer,Inside Micrometer,Dial Indicator,Go No Go Gauge,Dialgage,Eletronic,Digital Display Caliper,Automatic Height Gauge,Precision Level 2 Detector,Precision Block Gauge,00 Levels Of Marble Platform/Ring Gague,Etc; |

| Tolerance | 0.005~0.1mm; |

| Quality Assurance | ISO9001:2008 Certified,SGS Certification; |

| Color | Nature,White,Black,Red,Yellow,Blue,Green,As per your requirment; |

Planetary Gear Picture

Why Choose Planetary Gear?

Planetary gears are a popular type of mechanical transmission for several reasons. They are self-aligning, compact and power dense.

However, they have some practical problems. They have high sliding forces, and a lot of motion, which means energy losses are a big problem.

It is self-aligning

Planetary gears are a type of helical gear arrangement that is more power dense and can be used to drive higher torques and reductions in a smaller package. They can also handle higher shock loads and overhung loads.

However, they are a bit difficult to align. Many planetary drives are mounted on a carrier, which is not easily visible during assembly, and this makes it difficult to ensure that all of the planet gears are properly aligned for simultaneous engagement with the ring gear and sun gear.

Therefore, one of the most important aspects of planetary gearing is that it is self-aligning. This is achieved through a method that includes inserting a tool into the bore in the front face of the carrier and radially expanding the fingers from the central position to engage and index the planet gears.

In addition to radially expanding the fingers, this method also includes inserting hollow axles 64 and 66 into bevel gears respectively 68 and 70 and screwing plugs 75 and 80 into sleeve 76, where the hollow axles are held in threaded engagement with the bevel gears. This ensures that the planetary gears 72 and 74 remain oriented independent of the rotary motion of the hollow axles 64 and 66 as shown in FIGS.

It is compact

Compared to other gear types, planetary gearboxes are compact and boast a high power density. They are especially suitable for applications in which space is an issue.

Planetary gears are often used in combination with ring gears to provide a greater range of transmission ratios. Often they are placed in a single housing.

These planetary gears can also be used as summation or distribution gears to distribute the power between two shafts. This is common in automotive applications (differential gears) and hybrid vehicles.

Planetary gears are very accurate with almost no backlash. They are also modular and can be stacked to form a series of gear stages with a higher power transmission efficiency.

It is power dense

Planetary gear is power dense, and is a great option for applications that require high torque capability. It’s also more durable than traditional helical or spur gears, and is capable of handling higher shock loads and overhung loads.

Another advantage of planetary gear is that it is highly efficient and doesn’t waste energy on mechanical losses. In addition, it’s modular and can be stacked to increase its power density.

Planetary gears are a great choice for automation systems, as they can be used to increase torque while slowing down the speed of servo motors. They are used in automated guided vehicles (AGVs), pipe bending machines, and other motion control devices.

It is easy to maintain

Planetary gears are a popular choice for many industries. They can be found in a variety of applications such as tractors, construction equipment, and turbine engines.

They are easy to maintain as long as you choose the right type of housing. The gearbox should have an environment that is free of dirt, dust and moisture to prevent damage to the inner components.

One of the disadvantages of using planetary gearboxes is the loss of lubrication which can lead to premature wear and failure when running at high speeds. Using pressurized forced lubrication systems or grease lubricants can help alleviate this problem.